Best Applications and Machines for Tube Laser Cutting

Time : Jan 09, 2026 View : 642

In the world of metal fabrication, speed and precision are no longer just “nice to have” features; they are the baseline for survival. Whether you are building complex architectural frames or simple furniture components, the way you cut your tubes dictates your profit margin. This guide explores how modern fiber laser technology transforms raw metal into finished products with minimal effort. If you are looking for a partner that lives and breathes laser innovation, Wisecut provides the heavy-duty hardware and smart software needed to stay ahead of the competition.

Why Is Tube Laser Cutting Essential for Modern Manufacturing?

Precision and Efficiency in Metal Fabrication

Laser beams provide a level of accuracy that mechanical blades cannot touch. You get clean edges and tight tolerances every time. This means when your parts move to the welding station, they fit together perfectly without gaps or messy overlaps.

Reduction of Material Waste and Labor Costs

Nesting software calculates the best way to fit parts on a single tube. You save money by squeezing more parts out of every length of metal. Since the machine does the work of three traditional tools, you spend less on manual labor and more on growing your business.

Seamless Integration into Automated Production Lines

Modern machines talk to your design software. You can send a CAD file directly to the equipment, and it starts cutting immediately. This digital bridge removes the human error that usually happens when someone has to manually measure and mark a workpiece. According to a 2024 fiber laser market report by MarketsandMarkets, this level of system integration also contributes to measurable efficiency gains, as modern fiber laser systems achieve approximately 85–90% electrical efficiency, significantly higher than traditional CO₂ lasers, resulting in lower energy consumption and reduced long-term operating costs.

Comparison of Tube Cutting Technologies Used in Metal Fabrication

| Параметр | Fiber Laser Tube Cutting | CO₂ Laser Tube Cutting | Traditional Sawing & Drilling |

|---|---|---|---|

| Typical Electrical Efficiency | 85–90% | 10–15% | Not applicable |

| Positioning Accuracy | ±0.03 mm | ±0.05–0.1 mm | ±0.3–0.5 mm |

| Secondary Processing Required | None or minimal | Occasional deburring | Mandatory (deburring, drilling) |

| Cutting Speed (Carbon Steel Ø50 mm Tube) | Высокий (up to 2–3× faster than sawing) | Medium | Low |

| Capability for Complex Holes & Bevels | Integrated in one process | Ограниченное | Requires multiple tools |

| Typical Maintenance Frequency | Low | Medium–High | Высокий |

| Совместимость автоматизации | Excellent (CAD/CAM direct) | Moderate | Poor |

Which Industries Benefit Most From Advanced Tube Cutting?

Structural Engineering and Construction Machinery Fabrication

Building skeletons and crane arms require massive strength. Tube lasers handle large-diameter pipes and heavy-walled sections with ease. You can find more about specialized industry setups in the Wisecut solutions section, where they detail how to tackle these heavy-duty tasks.

Household Appliances and Kitchenware Manufacturing

From the legs of a dining table to the internal frame of a washing machine, the finish must be flawless. Laser cutting leaves no scratches and requires zero deburring. This helps you get products to market faster without worrying about aesthetic defects.

How Does Wisecut Ensure Superior Cutting Performance?

The secret to a great cut isn’t just the laser beam; it is the “bones” of the machine. If the frame shakes even a tiny bit, your precision disappears. That is why professional-grade equipment uses a plate-welded body that undergoes heat treatment to remove internal stress. This ensures the machine stays true for over 20 years.

Heavy Duty Plate Welded Machine Body Stability

A solid foundation prevents vibration during high-speed moves. The bed is often processed by large-scale gantry milling machines to ensure the rails are perfectly flat. This level of “over-engineering” is why these machines don’t lose accuracy after a few years of hard work.

Aviation Aluminum Cross-Beam for High Speed Agility

While the base needs to be heavy, the moving parts need to be light. Third-generation aviation aluminum beams offer high strength and low weight. This allows the cutting head to zip around corners and accelerate rapidly without overshooting the mark.

Integration of Industry Leading Raycus Laser Sources

The heart of the system is the fiber laser source. By using top-tier brands like Raycus, you get a stable beam and a long service life. These sources are known for their high photoelectric conversion efficiency, which basically means they use less electricity to produce more cutting power.

What Are the Best Machine Options From Wisecut?

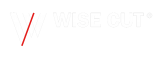

Высокопродуктивная машина для лазерной резки с полной крышкой

This is the workhorse for shops that demand total safety and high power. The High performance Full cover laser cutting machine features a protective enclosure that keeps the work area clean and the operator safe from reflections. It is perfect for high-wattage applications.

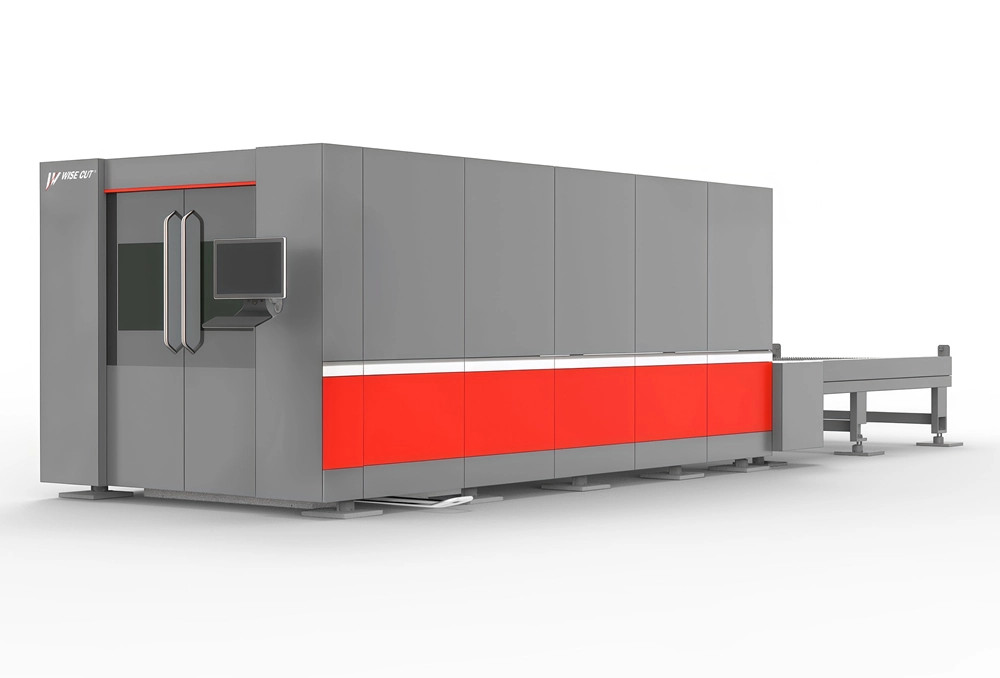

Машина для лазерной резки листа металла одной платформы

If you have limited floor space but still need professional power, the Single Platform Metal Sheet Laser Cutting Machine is a smart choice. It is easy to load and provides an open view of the cutting process, making it great for custom jobs and shorter runs.

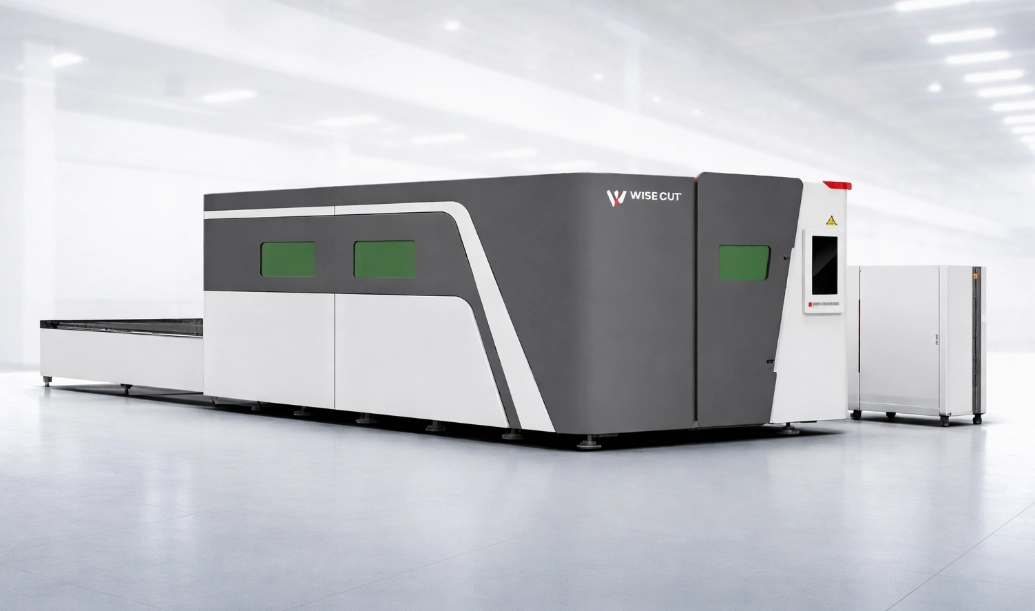

Полная закрытая металлическая лазерная резачная машина

For those prioritizing a clean shop environment, the Full Enclosed Metal Laser Cutting Machine offers an integrated dust extraction system. It keeps the smoke and fumes inside the cabinet, which is a huge plus for meeting environmental regulations and keeping your team healthy.

How Do Automation Features Optimize the Workflow?

Automated Sheet Loading and Unloading Systems

Manual loading is the biggest bottleneck in any factory. Automated systems can pick up a tube or sheet and place it on the bed while the machine is still finishing the last part. This keeps the laser firing almost 100% of the time.

Reduced Manual Intervention and Improved Safety Standards

The fewer times an operator has to touch the machine while it is running, the better. Light curtains and emergency stop buttons are standard, but the real safety comes from the enclosed designs and intelligent software that prevents crashes before they happen.

What Materials Can Be Processed With Wisecut Technology?

You aren’t limited to just one type of metal. A fiber laser is like a Swiss Army knife for fabrication. It is funny how some people still think lasers can only handle thin stuff, but modern high-power units can slice through thick plate like it is butter.

Carbon Steel and Stainless Steel Versatility

These are the bread and butter of the industry. Whether it is 1mm or 25mm, the laser produces a bright, smooth finish on stainless and a clean, sharp edge on carbon steel. Nitrogen or oxygen assist gases help tailor the edge quality to your needs.

Highly Reflective Brass and Copper Processing

In the past, reflective metals were a nightmare for lasers because the light could bounce back and damage the machine. Modern fiber lasers use specialized optical isolators that allow you to cut brass and copper without any risk to the equipment.

Specialized Alloys Including Titanium and Manganese

For aerospace or high-end automotive work, you might need to cut exotic alloys. The control systems allow for precise heat management, so you don’t ruin the properties of the metal while you are cutting it.

Why Is Wisecut a Trusted Global Partner?

Professional 24/7 Remote Diagnostics and Global Support

If something goes wrong, a technician can often log into your machine remotely to fix software issues or diagnose hardware problems. This saves you days of waiting for a person to fly to your site. You can reach out through the contact us page to see how they handle local service.

Over 300 Patents and Strong Research Abilities

This isn’t just about assembling parts. It is about inventing better ways to cut. With a massive library of patents, the technology stays fresh. You can read about their latest breakthroughs in the news center to see what is coming next.

Bespoke Engineering Solutions for Specific Client Needs

Every shop is different. Sometimes you need a longer bed, a specific chuck size, or a custom loading system. A good manufacturer listens to your specific problems and modifies the machine to fit your floor plan and your goals.

Часто задаваемые вопросы

Q1: What is the maximum thickness a tube laser can cut?

A: The maximum thickness varies based on the laser power. For instance, a 3000W source usually manages up to 20mm of carbon steel. Higher power units, on the other hand, can process even thicker materials.

Q2: Can these machines cut square and rectangular tubes?

A: Yes, the smart chucks and software easily manage round, square, rectangular, and even D-shaped or oval tubes. They deliver high precision in every case.

Q3: Is it difficult to learn the software for laser cutting?

A: Most operators pick up the basics within a few days. The software often includes a simple “one-button” nesting feature. This tool handles the complex tasks for you.