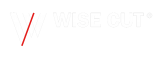

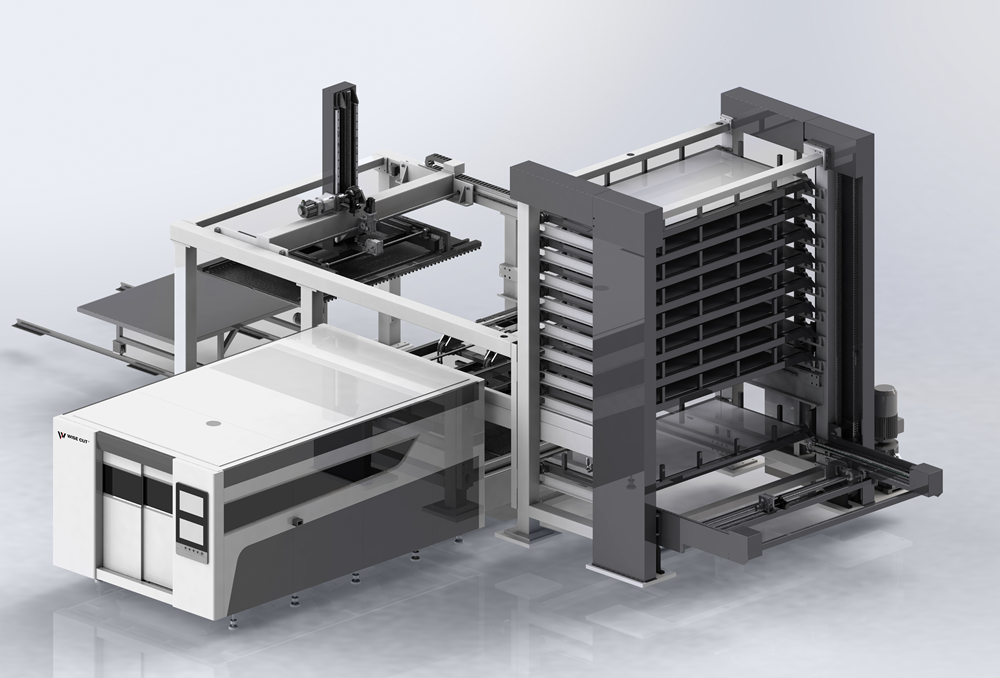

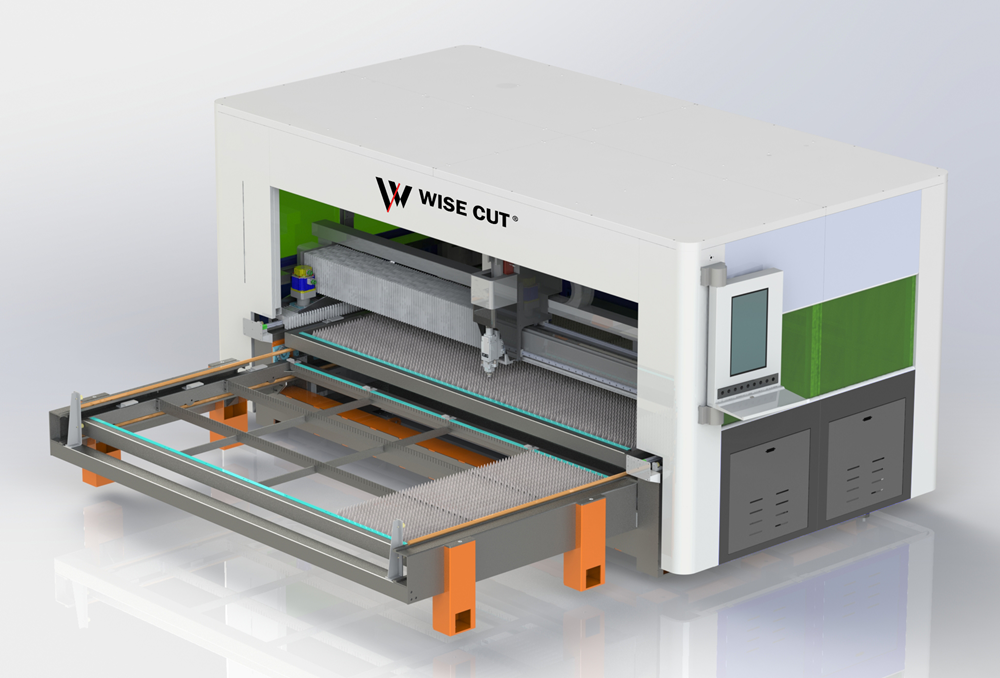

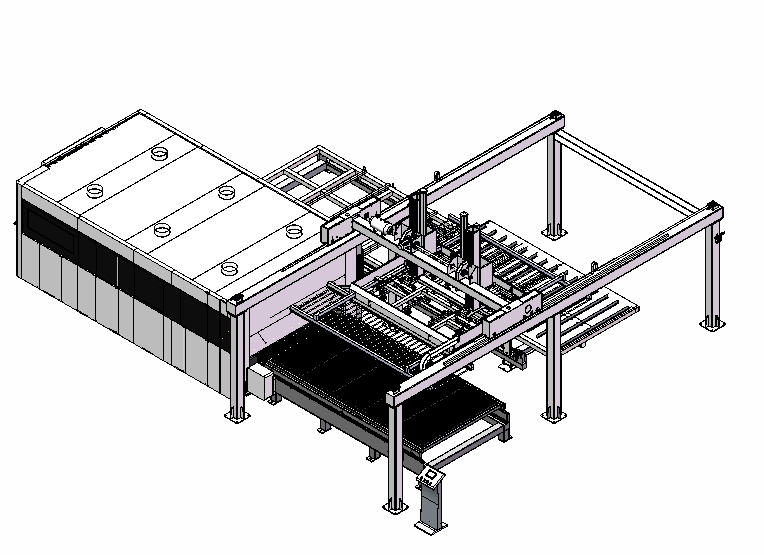

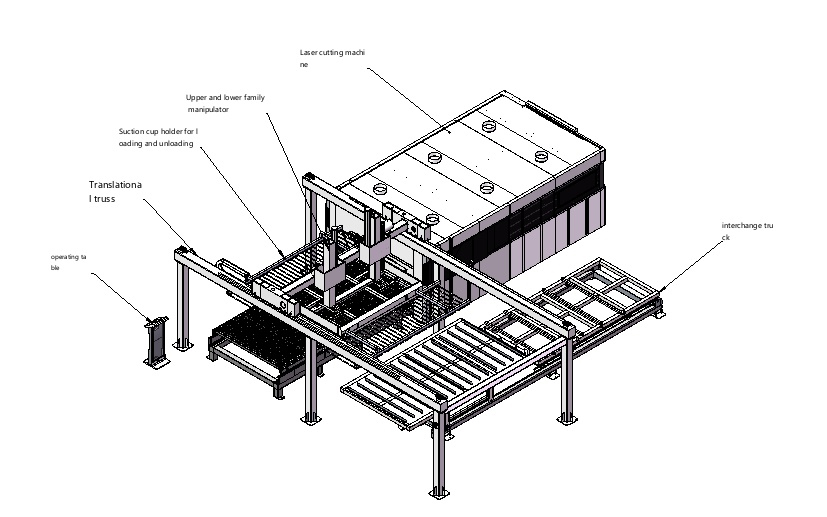

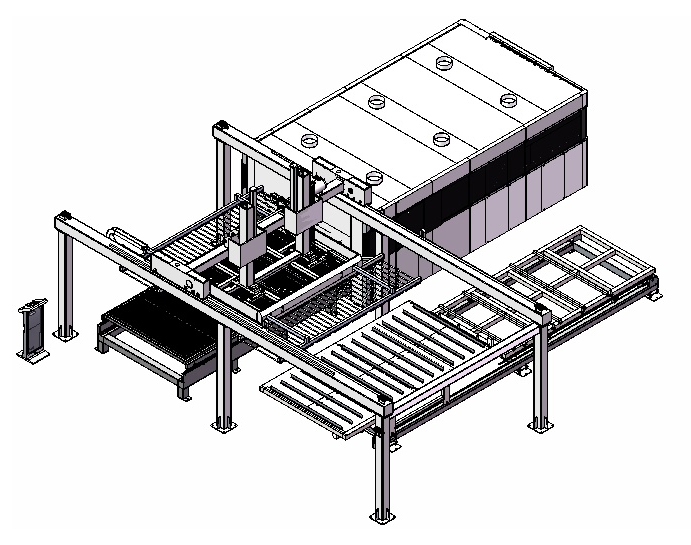

This system consists of a laser cutting machine loading and unloading composite truss robot, a double-layer electric exchange trolley, a CNC control system, a vacuum control system, and other components. Together with the laser cutting machine, it forms an automated sheet metal production unit. This system automatically loads and unloads sheets, effectively improving production efficiency and reducing costs.

Technical Solution

a. Technical Parameters:

1. This system consists of a laser cutting machine loading and unloading composite truss robot, a double-layer electric exchange trolley, a CNC control system, a vacuum control system, and other components. Together with the laser cutting machine, it forms an automated sheet metal production unit. This system automatically loads and unloads sheets, effectively improving production efficiency and reducing costs.

2. The robot is driven by a servo motor through a precision reducer, with a total lifting stroke of 700mm and a traverse distance of 5500mm (adjustable based on actual conditions).

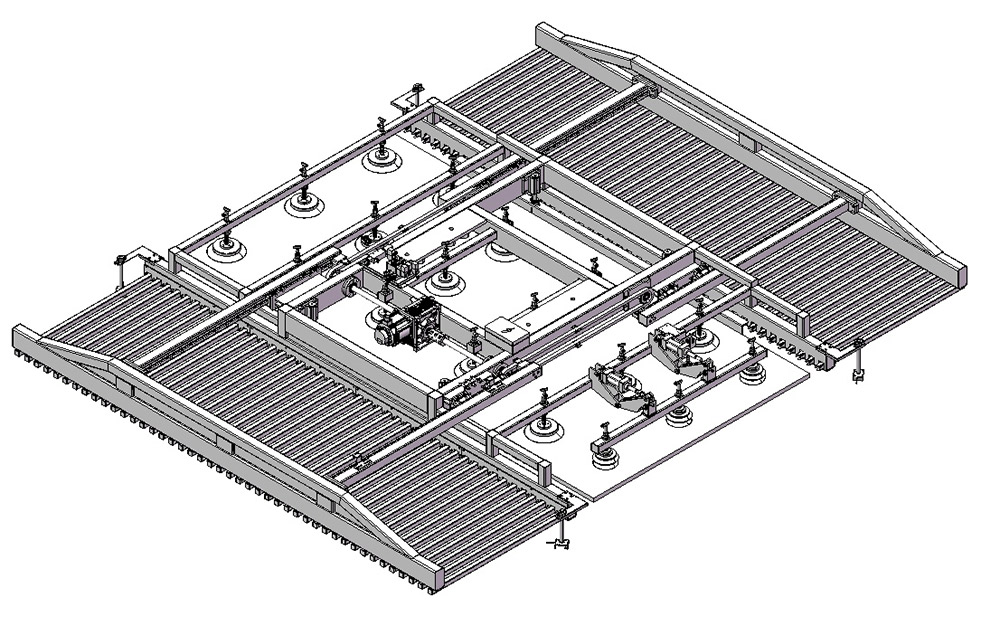

3. Multiple sets of OPDEPO brand vacuum, oil-resistant suction cups are installed, each equipped with a manual valve for manual closing and closing according to the sheet material size. The loading robot has a repeatability accuracy of ±2mm.

4. A pneumatic sheet separation device is installed at the end to facilitate sheet separation during automatic loading. Note: Due to differences in sheet adhesion and oil content, manual assisted sheet separation can be used as needed.

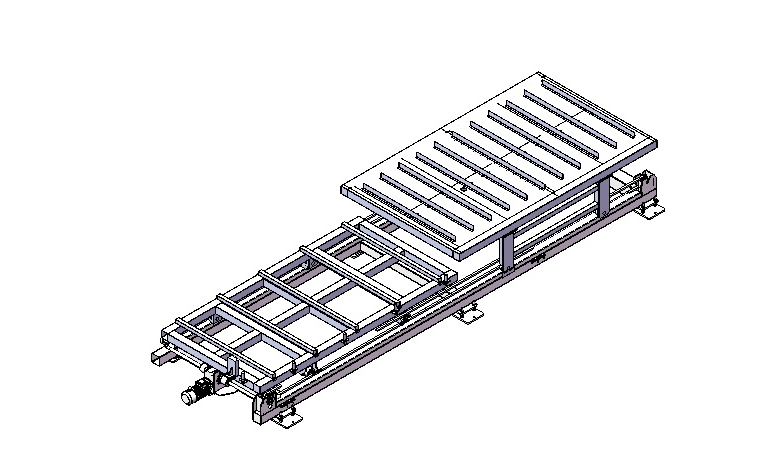

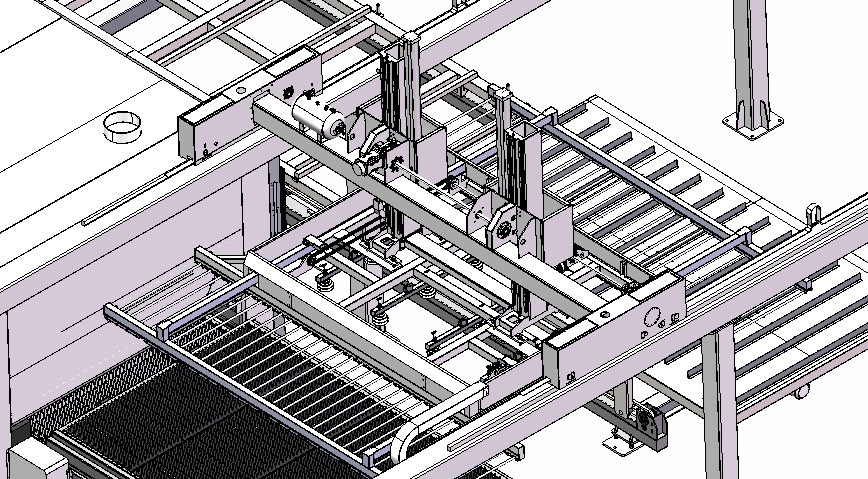

5. The automatic loading and unloading system is equipped with a double-layer electric trolley (upper layer) to store finished material frames and scrap material for the laser machine after cutting, and a second electric trolley (lower layer) to supply raw material to the laser machine.

6. The trolley is driven by a reduction motor and equipped with an electromagnetic brake. It is equipped with a movable magnetic separator to facilitate sheet separation by attracting the sheet material, increasing the success rate of sheet separation.

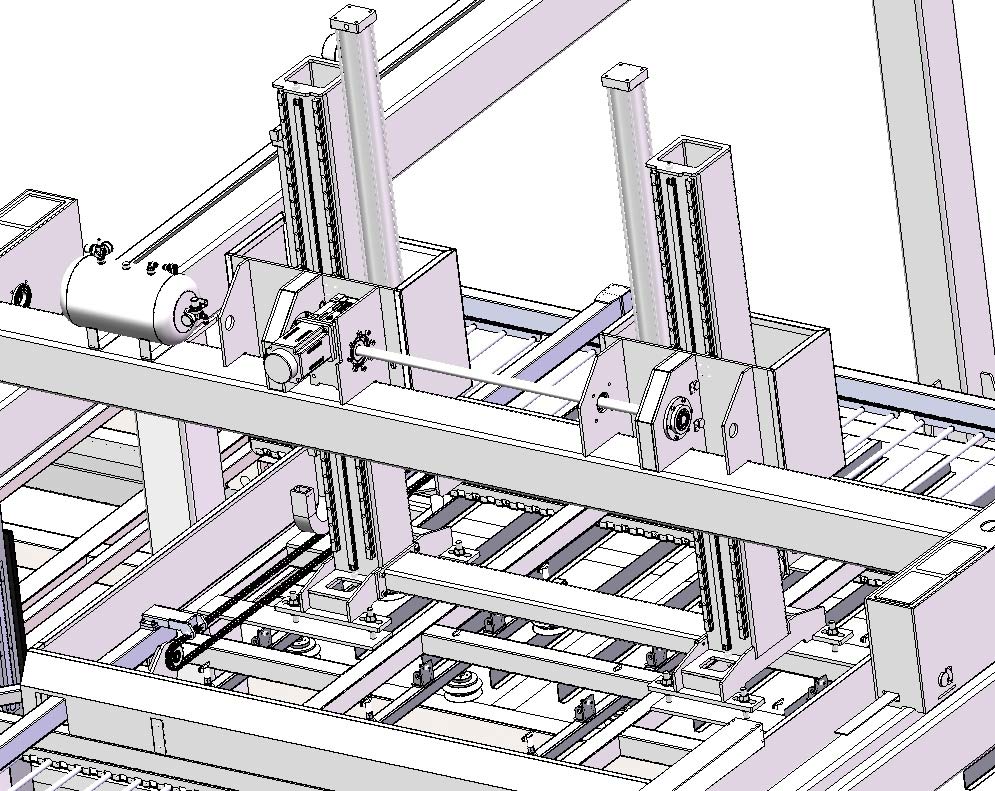

7. The unloading mechanism utilizes a dual-fork unloading manipulator and loading suction cup connected to a single lifting column structure. This left-right dual-fork unloading mechanism shortens the unloading fork’s travel distance and reduces malfunctions.

8. The equipment is fully servo-driven. High-power servo motors drive the manipulator’s lifting and traversing operations. The lifting mechanism utilizes linear guides, ensuring high speed and positioning accuracy.

9. The control system utilizes an imported 10-inch touch screen and an intelligent CNC system with an Omron programmable controller. It features both automatic and manual operation modes. All settings, monitoring, and debugging can be performed quickly and easily via touchscreen.

10. The operating environment for this machine should meet the requirements of a temperature range of -10-45°C, a relative humidity of less than 80%, and good lighting. The environment should be free of flammable and explosive substances, strong electromagnetic interference, corrosive gases, or splashing liquids.

Technical Parameters

Maximum Loading and Unloading Plate Size | 4000*2000 | mm |

Minimum Loading and Unloading Plate Size | 1200*1000 | mm |

Maximum Loading and Unloading Plate Thickness | 20 | mm |

Minimum Loading and Unloading Plate Thickness | 0.8 | mm |

Maximum Loading and Unloading Plate Weight | 1300 | kg |

Single-Layer Loading Weight of the Exchange Cart | 3 | T |

Single-Layer Loading Height of the Exchange Cart | 200 | mm |

Robot Translating Speed | 10-30 | m/min |

Robot Lifting Speed | 5-10 | m/min |

Electric Cart Exchange Speed | 10 | m/min |

Equipment Power | 10 | Kw |

Equipment Air Inlet Pipe | 12 | mm |

Equipment Air Source | 0.6-0.7 | Mpa |

Power Supply Requirements | 3-phase 5-wire 380V |

|

b. User Guide:

1. The user can switch between automatic and manual loading modes using the touchscreen to suit different working conditions.

2. Loading method: The bottom split fork opens, and the internal vacuum suction cup picks up the plate. The lifting axis lifts and moves horizontally to the laser machine, placing the sheet on the laser platform.

3. The unloading mechanism utilizes a motorized, left-right double-fork structure. The unloading forks have a short travel distance and a low failure rate. The opening and closing forks utilize steel square tube tines, which offer high load capacity and strong deformation resistance. The forks also minimize contact with the sheet, preventing scratches. The double forks open and close synchronously in both directions along linear guideways and are driven by an electromagnetic brake motor.

4. The loading and unloading robot is constructed from manganese steel pipes and high-quality steel plates welded together, treated with vibration stress relief, and machined on a large CNC gantry milling machine. It offers excellent rigidity and precision. The gantry beam and outriggers are connected by adjustment bolts, allowing for easy adjustment of the beam’s levelness. The loading and unloading robot is driven by a servo motor via a precision reducer and equipped with imported linear guides. A synchronous balancing cylinder has been added to the lifting mechanism to enhance high-speed lifting stability and prevent vibration during movement.

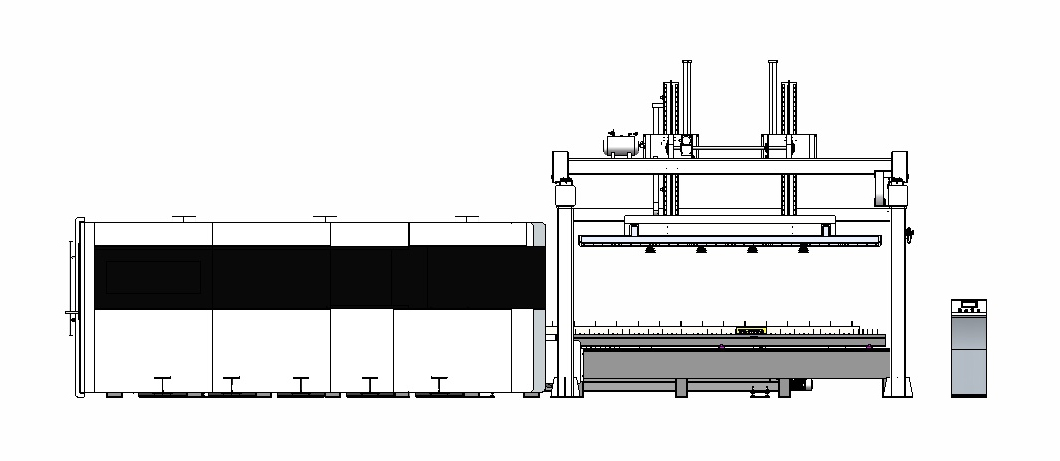

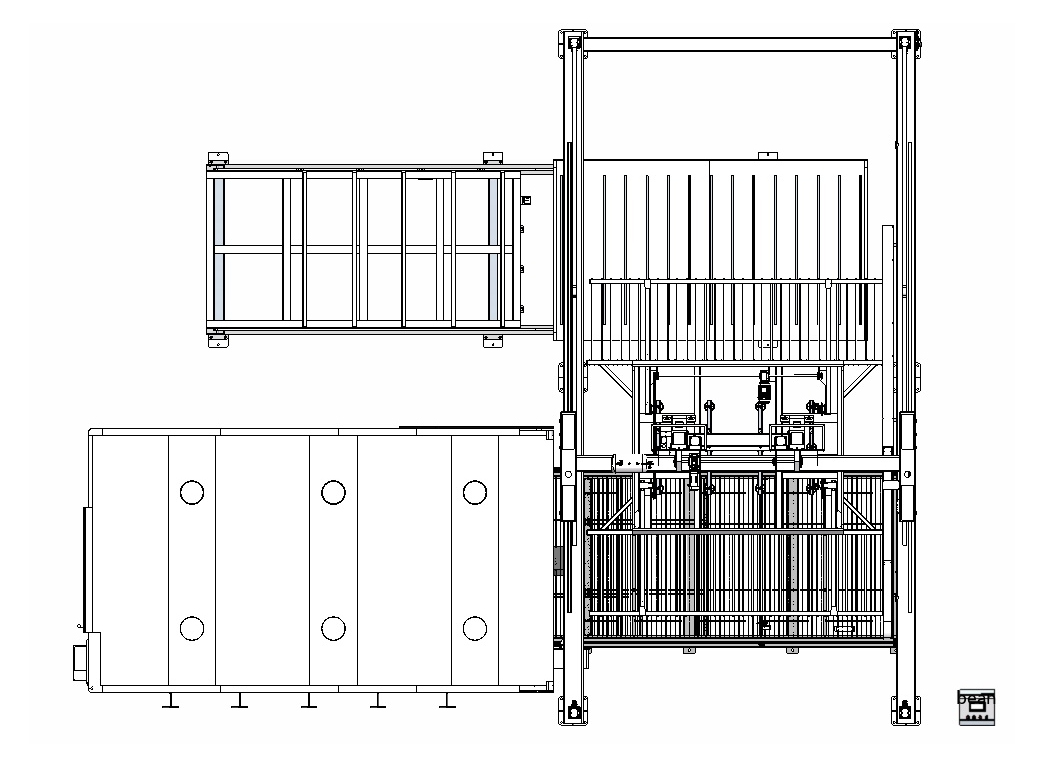

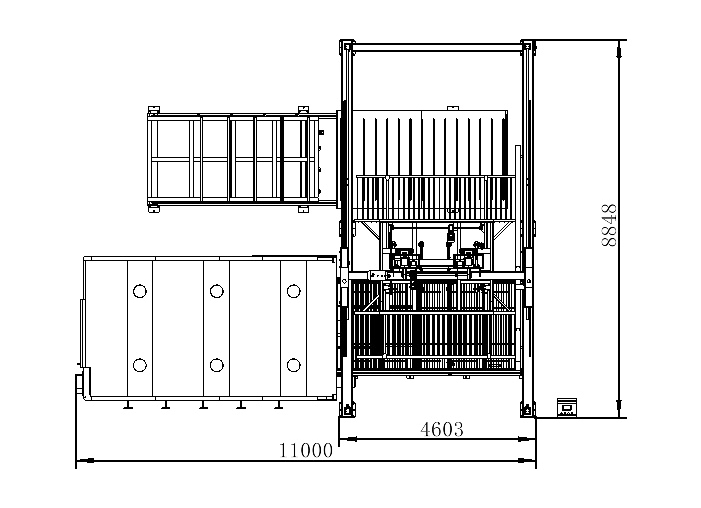

c. Rendering and dimensional drawing:

d. Equipment key components configuration list:

Serial number | Name Title | Product Brand | Spare parts Notes |

1 | Guide rail | SMG |

|

2 | Touch screen human-machine interface | Shanghai Fanyi |

|

3 | Vacuum controller | SNS |

|

4 | PLC | Japan OMRON Omron |

|

5 | DC power supply | Japan OMRON Omron |

|

6 | Relay | Japan OMRON Omron |

|

7 | Pneumatic components | SNS |

|

8 | Suction cup | OPDEPO |

|

9 | Servo motor | Ruineng |

|

10 | Reducer | Shanghai Yintong Guzuo Mechanical Force |

|

11 | Rolling Bearing | Shanghai Renben | Maintenance-Free |

12 | Photoelectric Sensor | Shanghai Hugong |

|

13 | Circuit Breaker | Delixi |

|

14 | Chain | Hangzhou Donghua |

|

e. Pre-installation Preparations

1. Prepare a 380V60A power supply and connect it to the device with a 5-core 10mm² power cable.

2. Compressed air source with a working pressure of 0.6MPa and the air pipe connected to the equipment.

3. Install safety warning signs and operating procedures in the equipment’s working area.

f. Safety Precautions:

1. Operators are prohibited from entering the working area of removable equipment within the working range.

2. Personnel entering the working area must receive safety training.

3. Before operating the robot, confirm that the operating conditions are met.

Related Products

WISECUT 40TX1200MM CNC Press Brake Electric Model

WISECUT 40TX1200MM CNC Press Brake Electric ModelMachine Body Controlling System Controlling Cabinet Servo Motor (Electric Servo Motor) Rear Gauge + Baffle Finger Quick Clamping Upper and Lower Molds Oil Lubrication R Axis Rack & Pinion GIVI Magnescale Taiwan Guide Rail Technical Parameter: Item Parameters Unit Bending Power 40 Ton Bending Length 1250 mm Distance between columns 950 mm Throat depth 300 […]

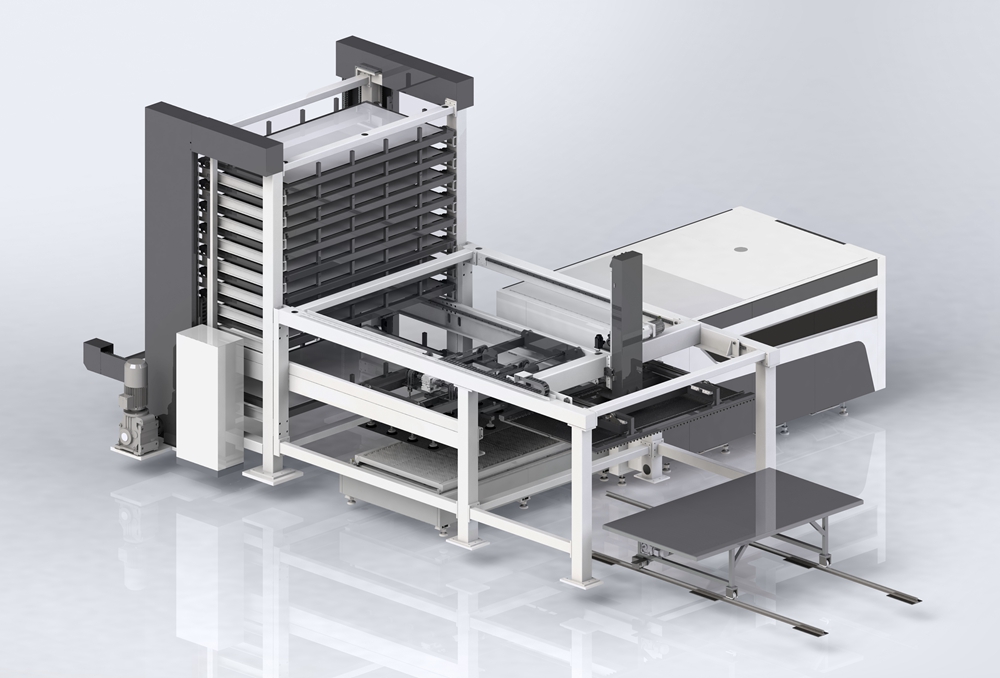

High performance Full cover laser cutting machine

High performance Full cover laser cutting machineMachine table: 1) Super stable heavy duty plate welded machine body especially for high power lasre cuting . 2) Built for stability. Mortise and tenon welding process ensure that the bed with sufficient structural stability, shock resistance. 3)Highly efficient heat dissipation and dust removal can longer machine lifetime. Machine beam: 1) Aviation-grade aluminum beam with […]

Single Platform Metal Sheet Laser Cutting Machine

Single Platform Metal Sheet Laser Cutting MachineMachine Body: 1) Machine bed with welded steel plate, high rigidity. 2) Machine bed is temper heat treatment,delete weld stress and ensure no deformation 3) Machine bed install rail, processing materials by gantry working center, ensure install surface flatness error of 0.02mm (Weld temper heat treatment lather bed) Aviation Aluminum Beam 1) Laser Machine Beam with […]

Space Saver Full Cover Fiber Laser Cutter

Space Saver Full Cover Fiber Laser CutterMachine table 1) Machine table is plate welding structure, after annealing at high temperatures to prevent deforming, to ensure cutting precision. 2) Built for stability. Mortise and tenon welding process ensure that the bed with sufficient structural stability, shock resistance. Machine beam 1) beam structures are with high intensity,corrison-proof and anti-oxidant, enhanced the cutting speed. […]

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail