2026 Latest – How to Choose a Laser Tube Cutting Machine

Time : Jan 08, 2026 View : 655

As you step into 2026, the landscape of metal fabrication is moving faster than ever. If you are looking to upgrade your workshop, you’ve likely noticed that a standard flatbed laser just doesn’t cut it for complex pipe work anymore. Choosing a laser tube cutting machine is a big investment, and the options can feel overwhelming. You need a partner that doesn’t just sell a box, but offers a complete solution. This is where Wisecut, a high-tech enterprise with over 300 patents and a massive 60,000 square meter production base, comes into play. They follow a “Friendly 4” principle: easy installation, easy operation, easy service, and easy maintenance. Whether you are building furniture or heavy industrial frameworks, finding the right machine starts with matching the hardware to your specific daily headaches.

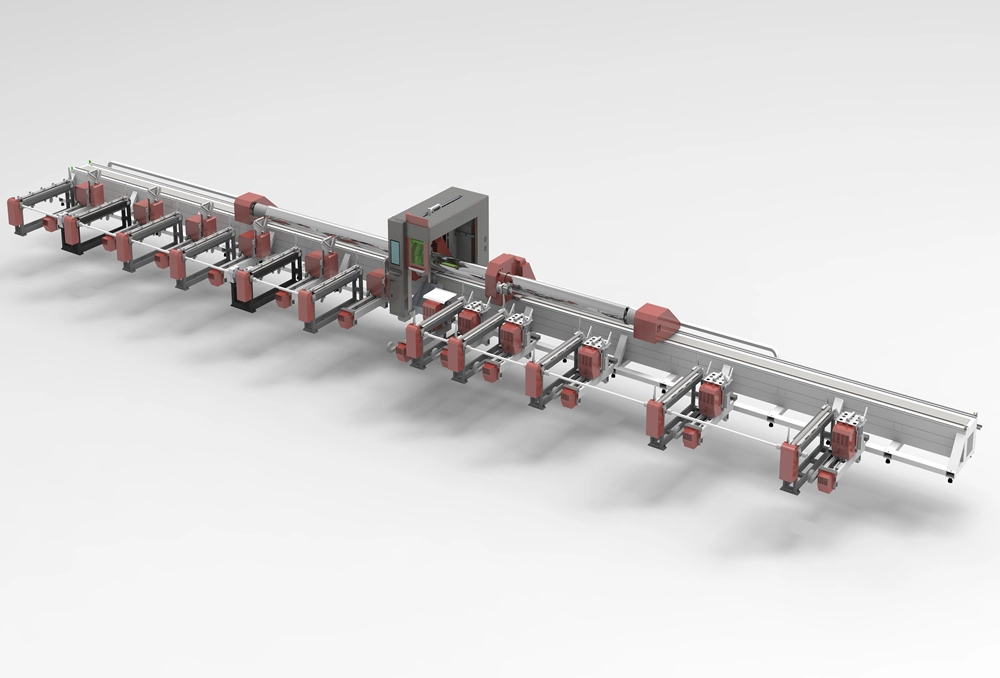

Why Is the Number of Chucks the First Decision You Should Make?

The chuck is the heart of any tube laser. It grips, rotates, and feeds the material. In the past, people just bought whatever was cheapest, but now the industry focuses on “tailings”—that wasted piece of pipe at the end that you can’t cut. If you are processing thousands of tubes a month, those 200mm scraps add up to a lot of lost money. You have to decide if you need a simple setup or a complex multi-chuck system that can practically reach around itself to finish a cut.

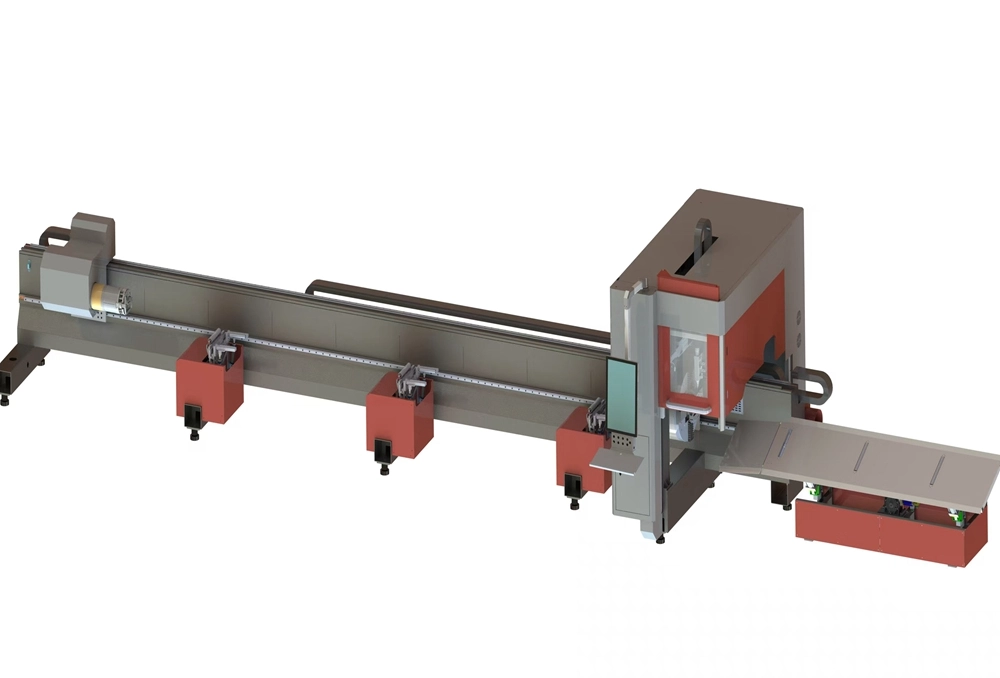

Efficiency Gains of the Two Chuck Pipe Laser Cutting Machine

For many shops, the Two Chuck Pipe Laser Cutting Machine is the bread and butter of production. It is perfect for standard lengths, usually around 6 meters, and handles common shapes like round, square, and rectangular tubes with ease. If your work doesn’t involve massive, heavy beams, this setup gives you the fastest return on investment because it’s simple to run and very quick on the uptake.

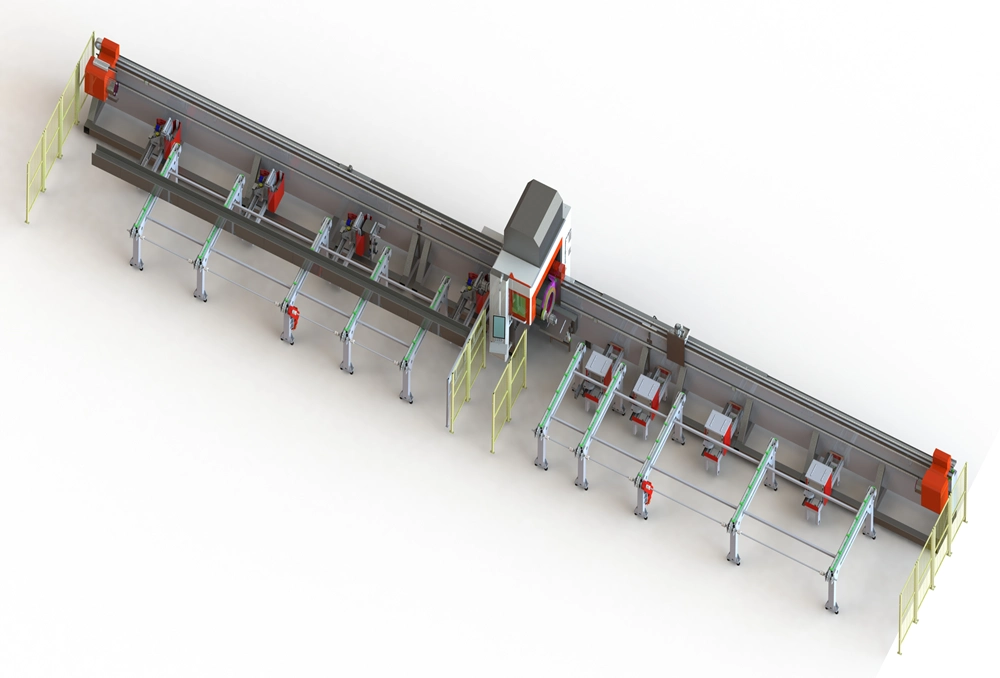

Stability Benefits of the 3 Chuck Heavy Duty Tube Laser Cutting Machine

When you move into heavier territory, a third chuck acts like an extra set of hands. The 3 Chuck machine de coupe laser de tube lourd provides middle support that prevents long, heavy pipes from sagging or whipping during high-speed rotation. This extra stability means your cuts stay precise even at the far end of a 9-meter pipe, and it helps pull the material through to significantly reduce waste.

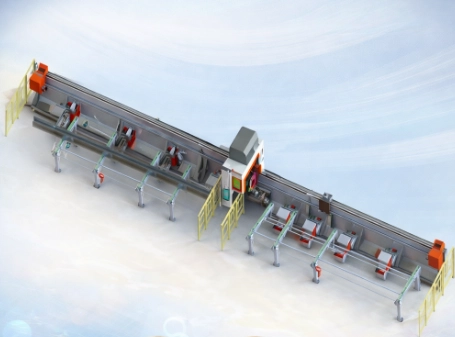

Zero Tailings Performance of the 4 Chuck Profile Heavy Laser Tube Cutter

If you absolutely hate wasting material, the 4 Chuck Profil lourd Coupe de tube laser is the top-tier choice for 2026. With four independent chucks, the machine can hand off the tube from one to another, allowing the laser head to cut right up to the very edge. It’s a beast for heavy profiles and U-shaped or H-shaped steel, making it the go-to for structural engineering firms that need every millimeter to count.

How Does Laser Source Quality Impact Your Long-Term Production?

You might be tempted to save a few dollars on a no-name laser source, but that is a recipe for downtime. In the fiber laser world, the source is the engine. If the engine fails, the whole car stays in the garage. You want a source that has a high photoelectric conversion rate, meaning it turns electricity into cutting power without generating excessive, machine-damaging heat.

Integration of Genuine Raycus and Max Laser Sources

Reliable machines use sources from industry giants like Raycus or Max. These brands are battle-tested and come with actual warranties that mean something. When you use a genuine 1500W or 3000W source, you get a stable beam that cuts through 20mm carbon steel like butter, day in and day out, without the power dropping off after six months of use.

Importance of CE Certificated Electrical Components

It’s not just the laser; it’s the brains behind it. Using Schneider electric components and OMRON sensors ensures that the machine doesn’t have a “nervous breakdown” because of a cheap relay. Following CE standards isn’t just a legal hoop to jump through; it means the machine is wired safely so your operators don’t face unexpected hazards during a shift.

Extended Warranty and Global Support for Laser Modules

A good machine should come with a clear promise. Look for a two-year warranty on the main laser source and a manufacturer that offers 24/7 remote diagnostics. If something goes wrong at 2 AM, you need someone who can log in remotely to see if it’s a software glitch or a hardware fix, keeping your production line moving.

What Material Specifications Determine Your Machine Choice?

You can’t just buy a “standard” machine and hope it fits everything. You need to measure your thickest pipe and your heaviest beam before talking to a supplier. The physical weight of your raw material dictates the motor torque and the strength of the machine bed. If you put a 500kg pipe on a light-duty machine, you’ll ruin the precision rails in weeks.

Processing Range for Carbon and Stainless Steel

Most shops deal with a mix of carbon steel, stainless, and maybe some aluminum. Each requires different gas pressures and laser frequencies. A versatile machine handles everything from 1mm thin-walled furniture tubing to 25mm thick industrial piping. You should check the products page to see exactly which wattage matches your most common material thickness.

Impact of Tube Diameter and Wall Thickness

Diameter matters because of the chuck’s “swing.” If you are working with 300mm wide pipes, a standard small-chuck machine won’t even be able to grip it. Also, wall thickness determines if you need a specialized cutting head with autofocus. Autofocus is a lifesaver because it adjusts the focal point instantly as the material thickness varies slightly across a long pipe.

Precision Requirements for Complex Profile Cutting

Precision isn’t just about the laser; it’s about the mechanical movement. High-end machines utilize HIWIN square rails from Taiwan and Fuji servo motors from Japan. This combination allows for a positioning accuracy of $\pm$0.03mm. If you are doing mortise and tenon joints in steel, that level of accuracy is the difference between a perfect fit and a piece of scrap.

Why Should You Prioritize Automation in 2026?

Labor is getting expensive and harder to find. In 2026, a machine that requires a human to manually lift every pipe onto the bed is an anchor on your business. Automation isn’t just a luxury; it’s how you stay competitive against shops that can run “lights-out” shifts. You want a system that can handle the heavy lifting while your operator focuses on quality control.

Benefits of the Fiber Laser Cutting Machine with Auto Sheet Loading

An automatic loading system can feed a new pipe into the machine in seconds. While the laser is finishing the last cut, the loader is already picking up the next piece. This cuts down the “idle time” between jobs. It’s much safer too, as it reduces the risk of back injuries or dropped pipes in the workshop.

Reliability of the Intelligent CNC Control System

Modern systems like CypCut or similar specialized tube software make programming easy. You don’t need a PhD in coding; if you can use a smartphone, you can probably learn to run these interfaces. They include nesting software that automatically calculates the best way to fit your parts onto a tube to save as much material as possible.

Speed Improvements with High-Power Servo Drives

Speed is more than just how fast the laser moves; it’s about acceleration. A machine with 1.2G acceleration can zip between holes and notches much faster than an older model. This is achieved through high-torque motors and a lightweight but stiff aviation aluminum beam that doesn’t wobble when it stops suddenly at high speeds.

How Does Machine Bed Construction Affect Cutting Accuracy?

The best laser in the world is useless if it’s mounted on a shaky frame. A lot of manufacturers try to save money by using thin steel tubes for the frame, but those vibrate and warp over time. You want a “heavy-duty” bed. It’s the literal foundation of your work. If the foundation isn’t solid, your round holes will start looking like ovals after a few months of heavy use.

Stability of the Plate-Welded Integral Body

Top-tier machines use a plate-welded bed, often using 20mm thick steel. After welding, the bed goes through a process called “annealing” in a high-temperature furnace. This “relaxes” the metal, so it won’t warp five years down the line. It’s a hidden cost that cheap manufacturers skip, but it’s vital for long-term accuracy.

Precision of the Aviation Aluminium Cross-Beam

The cross-beam needs to be light so it can move fast, but stiff so it doesn’t flex. Aviation-grade aluminum is the standard here. It’s extruded and then machined to a flat surface. This keeps the cutting head perfectly level as it travels the length of the machine, which is especially important when you are cutting long 6-meter or 9-meter pipes.

Durability of Wear-Resisting TAIWAN HIWIN Rails

The rails are the tracks the machine runs on. Dust and metal shavings are the enemies of these rails. Using high-quality HIWIN rails with automatic lubrication systems ensures the machine stays smooth.

Is Wisecut the Right Partner for Your Customized Needs?

At the end of the day, you aren’t just buying a machine; you are buying a relationship. With over 1,000 machines shipped to more than 20 countries, they have the experience to handle international shipping, customs, and local voltage requirements without the usual headaches.

Proven Success in Precision Customization for European Markets

European and North American markets have very strict safety standards. Choosing a supplier that already exports to these regions means the machine likely already meets high-level safety and quality bars. Whether you need a specific color to match your brand or a custom bed length for extra-long irrigation pipes, they can usually tweak the design to fit.

Strong R&D Capabilities and Patent Portfolio

A company that invests in 300 patents is a company that is moving forward. It means they are solving problems like “how to cut faster” or “how to make the chuck grip tighter” themselves, rather than just copying someone else’s old design. This innovation trickles down into every machine they build, giving you a more refined tool.

Adherence to ISO 9001 and CE Standards

Quality control shouldn’t be a “maybe.” ISO 9001 certification means there is a paper trail for every bolt and every weld. Before any machine leaves the factory, it goes through a rigorous 72-hour aging test and accuracy checks with laser interferometers.

FAQ (questions fréquentes)

Q1: What is the maximum pipe length these machines can handle?

A: Standard models usually handle 6 meters, but heavy-duty versions can be customized for 9-meter or even 12-meter pipes depending on your factory space.

Q2: Can I cut square and oval tubes on the same machine?

A: Yes, the intelligent chucks and software are designed to automatically center and rotate various profiles, including square, round, oval, and even some U-shaped channels.

Q3: Do I need a technician to come to my country for installation?

A: While the machines are designed for easy setup, many buyers prefer a technician for the initial training. Remote video support is also available to walk your team through the process.

Q4: How often does the laser tube cutting machine need maintenance?

A: Daily tasks are simple, like cleaning the lens and checking the water chiller. More thorough maintenance, like lubricating rails, is usually done weekly or monthly depending on your shift volume.

Q5: What is the lead time for a custom-configured machine?

A: Generally, production takes about 30 to 45 days, plus shipping time to your port. It is always best to contact us directly to get an accurate timeline for your specific configuration.