2025 Best Fiber Laser Tube cutting machine

Time : Dec 30, 2025 View : 680

In the current age of industrial production, where automation, quick operations, and exact measurements matter most, picking the proper fiber laser tube cutting machine turns into a smart choice for long-term growth. For the year 2025, those in manufacturing focus on equipment that blends strong power, smart automation features, and solid construction. This piece looks into the main aspects to think about when checking out these devices. It also points out why WiseCut emerges as a reliable ally in the changing world of smart metal handling.

What Are the Key Features to Look for in a 2025 Fiber Laser Tube Cutting Machine?

Selecting a top-notch fiber laser tube cutter means more than just checking the power level. It requires grasping how each setup aids in boosting output, sharpness, and ability to grow. These elements help ensure smooth daily work and future expansion.

Precision Cutting Performance and Beam Quality

The quality of the beam in a fiber laser device greatly affects how smooth the edges turn out and how much heat goes into the material. For fast cutting tasks, you need excellent lenses along with reliable movement parts.

The High Performance Full Cover Laser Cutting Machine delivers fine accuracy through steady power delivery. Its improved focusing setup keeps watch on room temperature, inner pressure, and lens condition. This way, it holds the best cut results even during nonstop use.

Moreover, Raycus laser sources in these setups provide strong electrical-to-light conversion rates and steady beam output. They cut down on power loss. At the same time, they give even, clean cuts every time.

Automation Capabilities and Workflow Integration

With larger batch runs and shorter deadlines, automation turns essential. Devices linked with clever software and mechanical aids improve the process from loading materials to arranging parts. This setup makes everything flow better.

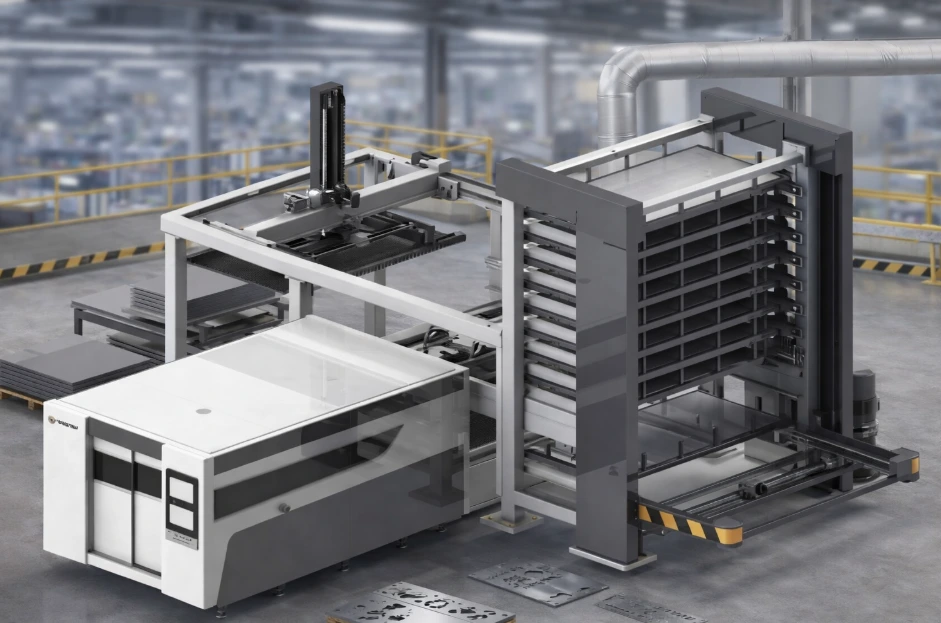

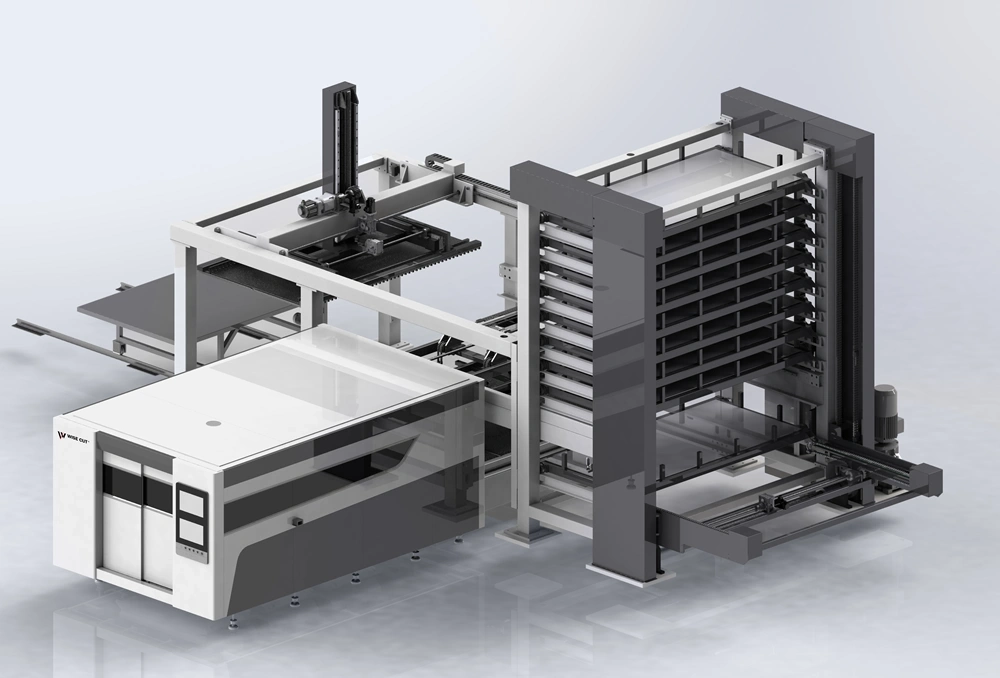

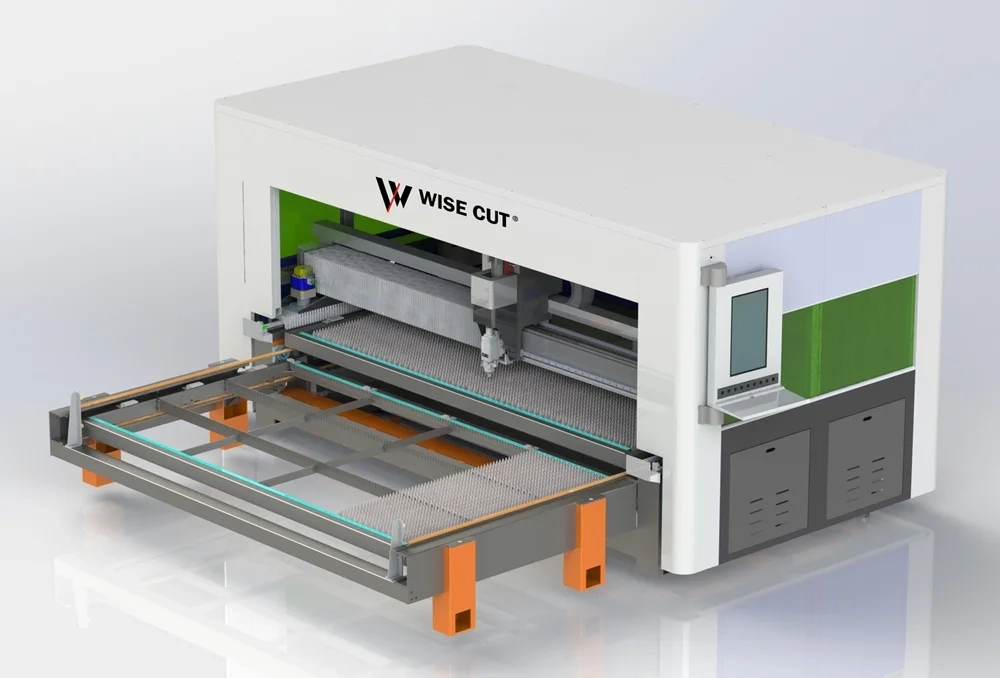

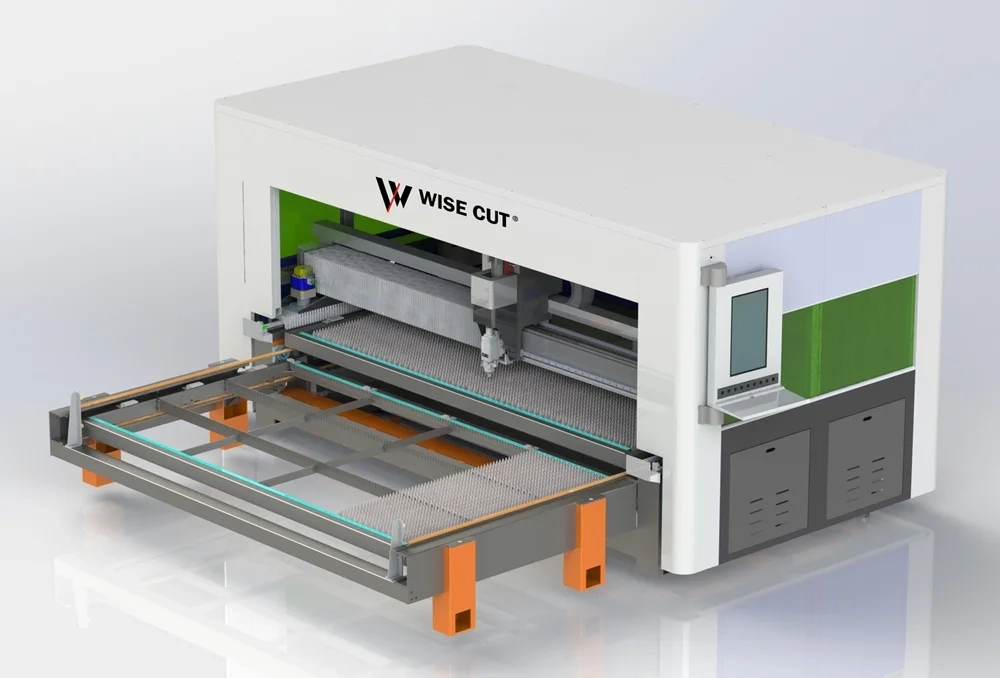

The Fiber Laser Cutting Machine with Auto Sheet Loading from WiseCut includes a complete automatic loading and unloading truss robot. It achieves ±2mm repeat accuracy. The system handles sheet loading and unloading on its own. As a result, it raises production speed and lowers expenses.

Modern control units let you connect easily to MES/ERP systems. This allows live tracking and planning. Such features prove vital in smart factory settings.

Build Quality and Structural Design

The strength of the mechanics makes sure that accuracy lasts through many years of work. Firm base frames, resistance to shakes, and protective covers all add to lasting strength and worker safety. These parts keep the machine running well over time.

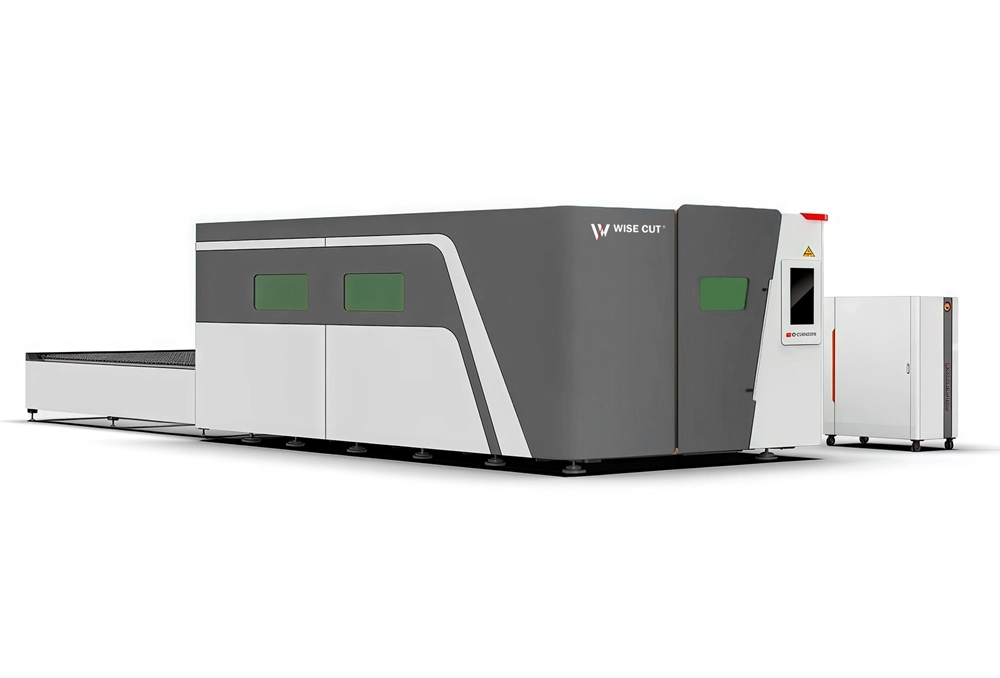

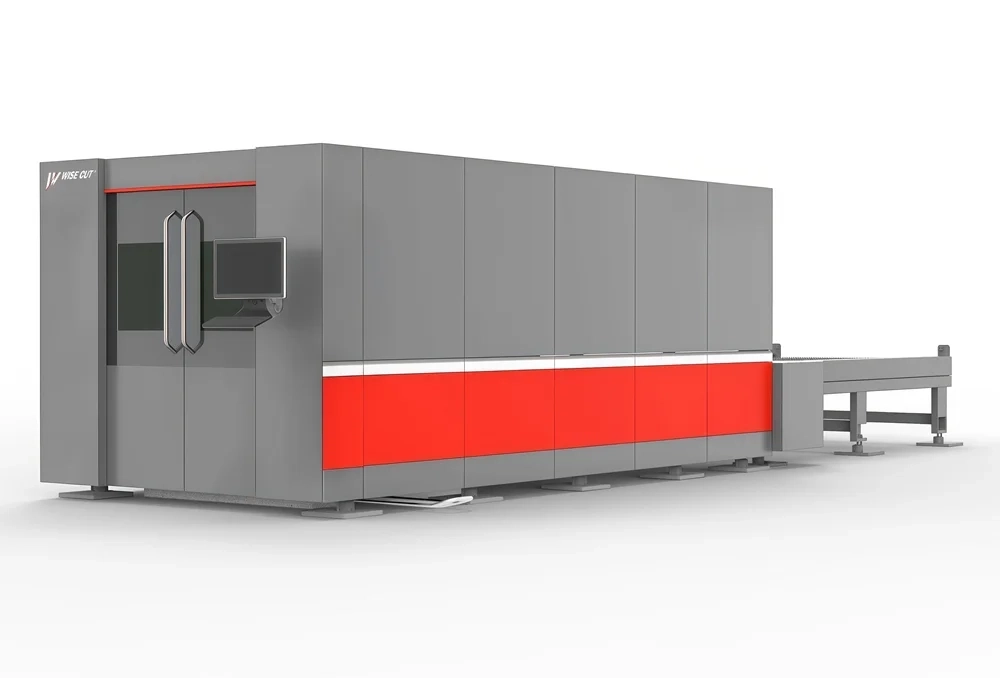

The Full Enclosed Metal Laser Cutting Machine provides a total closed setup for keeping operators safe. It also improves control over the surroundings. The bed frame uses high-strength materials. It stays steady during extended heavy use. This prevents any bending while running at top speeds.

How Does Cutting Efficiency Vary Among Leading Models in 2025?

Variations in cutting speed come from options in power, setup of the platform, and smart control of movements. All these play key roles in how much work gets done each day. They help match the machine to specific needs.

Power Configuration and Laser Source Options

Greater power levels allow quick work on thicker items without losing sharpness. WiseCut handles power up to 30kW. This covers light sheet work and tough jobs alike.

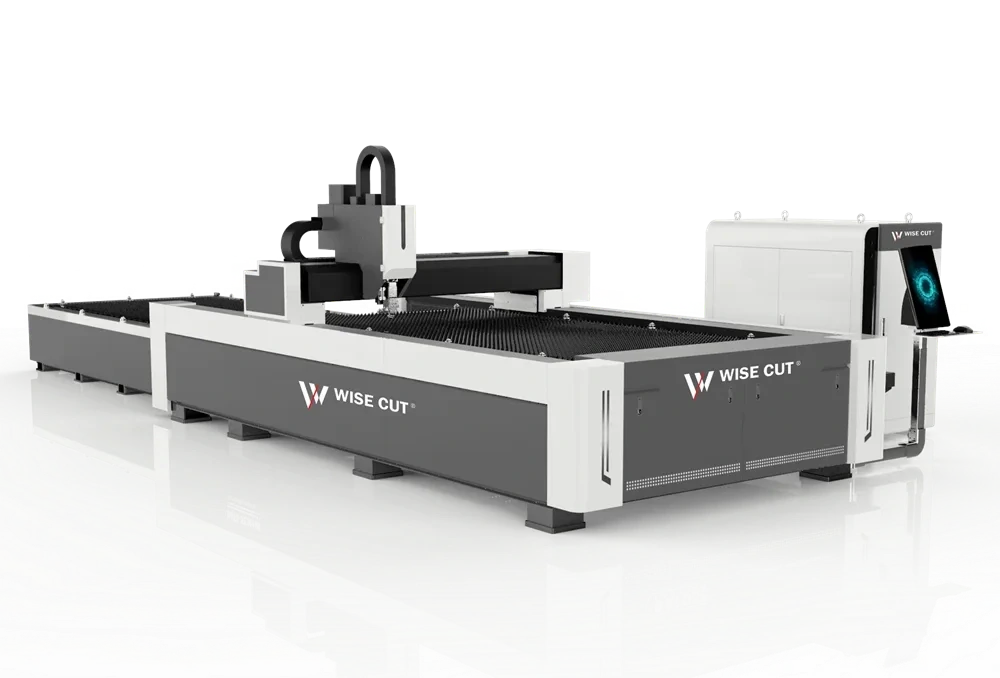

The Exchange Table Fiber Laser Cutting Machine works with power setups from 3kW to 12kW. It suits fast, adaptable, and big-scale cutting needs. This proves helpful for shops that take on many different orders.

Dual Pallet or Single Platform Operation Modes

The way the system is built affects not only the space it takes but also how smoothly work continues. Different modes fit various shop layouts.

Machines with two platforms, such as the Exchange Table model, let you prepare materials while cutting happens. This cuts down wait times. On the other hand, the Single Platform Metal Sheet Laser Cutting Machine fits well in tight spots. As an affordable option in a small size, it serves steel work widely. It reaches cutting speeds up to 100 m/min for runs with fewer items.

Intelligent Motion Control Systems

Sharpness in laser cutting comes not only from the lenses but also from how smoothly the machine shifts. Good control keeps everything on track.

Fast servo motors handle exact head movements. WiseCut uses Japanese Fuji servo systems in all its machines. It pairs them with Taiwan HIWIN rails and YYC helical racks. These ensure steady movement accuracy. They hold ±0.03mm position exactness, even under quick starts and stops.

Why Is Automation Critical in Modern Fiber Laser Tube Cutting?

Automation changes production setups by cutting the need for hands-on work. It also raises steadiness and the ability to track progress. These benefits make operations smoother overall.

Reduction of Manual Labor and Operational Costs

Automatic tools lessen mistakes by people, shorten stoppages, and speed up returns on investment. WiseCut’s auto-loading options greatly reduce time spent on manual tasks. They use servo-powered carts, suction grips for sheets, and smart PLC controls.

This kind of setup not only increases output but also eases the demand for trained workers. Such issues are common now with shortages in skilled help.

Seamless Integration with Smart Manufacturing Systems

Machines built for the future must fit into Industry 4.0 setups. WiseCut devices are made to link with these for smart factory work. They use Omron controllers for live checks. Plus, they have touch-screen panels for simple access to data on operations.

Enhanced Production Flexibility and Customization Support

Shifting from stainless steel tubes to aluminum shapes, or changing part layouts, requires adaptability. That is where flexibility counts most.

Flexible software in WiseCut systems adjusts settings based on the shape of parts. The Space Saver Full Cover Fiber Laser Cutter handles fast changes well. It has a pull-back cover and automatic pull for loading materials. These make setups quicker and easier.

How Does Safety Factor into the Design of 2025 Fiber Laser Cutters?

Meeting safety rules in industry is a must. This holds true especially for strong lasers that run over 100 m/min. Safe designs protect everyone involved.

Fully Enclosed Structures to Prevent Exposure Risks

Sealed covers shield workers from light rays and harmful gases. Devices like the Full Enclosed model include built-in air systems. These handle dust and smoke well.

Such setups let you run safely without adding many outside safety measures. They keep the work area clean and secure.

Real-Time Monitoring and Emergency Response Features

Sensors in the cutting head check for dirty lenses, heat in the chamber, and gas levels. Quick-stop buttons sit in easy spots for fast halts if trouble arises. Locks stop the machine if doors open or dangers show up. These features respond right away to issues.

Compliance with International Safety Standards

All WiseCut machines carry CE certification and follow ISO9001 rules. They meet CE, ISO, and other worldwide standards. This allows safe use anywhere, no matter the local rules.

What Role Does Design Play in Operational Efficiency?

Aside from basic functions, thoughtful layout affects how easy the machine is to use, how simple maintenance becomes, and how well productivity flows. Good design ties everything together for better results.

Space-Saving Configurations for Compact Workspaces

Places with little room gain from smart layouts like the Space Saver Full Cover Fiber Laser Cutter. This compact unit has full cover safety. It pulls out automatically for loading. Thus, it cuts extra steps for operators and eases setup or moving during installs.

Ergonomic Access Points for Maintenance

Panels that open without tools, parts that swap easily, and front access make upkeep straightforward. You can service without taking the whole unit apart. These reduce lost time during routine checks or swaps of components.

User-Friendly Interfaces to Streamline Operation

Smart control panels use touch controls with options for various languages. They show clear guides for fixing problems. This cuts the need for expert help in daily tasks.

How Do Different Models Cater to Specific Industrial Applications?

You should pick models that match your materials, output levels, and available space. Each type serves certain uses best. This ensures the right fit for your work.

High-Speed Cutting for Mass Production Lines

The Exchange Table Fiber Laser Cutter meets big-volume demands with two tables that change in less than 15 seconds. Its fast side-by-side swap keeps power steady. It also gives even cut surfaces. This suits round-the-clock setups with strict deadlines.

Versatile Configurations for Custom Fabrication Shops

For shops making different shapes or changing materials often, choose a flexible unit like the High Performance Full Cover Laser Cutting Machine. It has better tools for watching the beam. These keep accuracy steady across various metals. You avoid tough setup changes each time.

Heavy-Duty Construction for Thick Material Processing

Cutting up to 70mm thick needs strong builds. The Full Enclosed system uses tough bases with aircraft-level beams. They handle high heat without warping. This keeps performance reliable for demanding tasks.

Why Should Consider Wisecut as a Preferred Manufacturer in 2025?

Opting for WiseCut involves putting money into growing tech support. It comes with worldwide service networks and solid know-how. These elements build trust for ongoing success.

Comprehensive Product Line Covering Diverse Needs

From growing large runs to starting niche workshops, choices go from open tables to full auto enclosed units. Check out their complete selection at WiseCut Products.

Strong After-Sales Support and Global Service Reach

Quick 24/7 online checks plus engineers on site in 48 hours anywhere keep stops short. Service details cover parts delivery and help in multiple languages across regions. This support runs smoothly no matter where you are.

Proven Expertise in Intelligent Manufacturing Solutions

Clients from Europe to Asia-Pacific rely on WiseCut for custom builds. See About WiseCut for their research wins and worldwide growth. These efforts cement their place as a forward-thinking leader in industry.

FAQ

Q1: What’s the best fiber laser tube cutter for small factory spaces?

A: The Space Saver Full Cover Fiber Laser Cutter brings a small build with complete cover safety. It works great in tight shops while keeping strong results.

Q2: How does auto-loading improve my production line?

A: Automatic loading and unloading cut setup times a lot. They lower worker costs too. Plus, they guarantee steady accuracy. All this helps grow operations without hassle.

Q3: Can these machines cut both thin and thick metals?

A: Yes. Power options from 3kW to 30kW let models like the Full Enclosed Metal Laser Cutting Machine tackle thin stainless sheets and heavy carbon plates up to 70mm thick.

Q4: Are these machines compatible with Industry 4.0 systems?

A: Yes. WiseCut uses smart controls that link to MES/ERP for live checks and better production flow.

Q5: What makes WiseCut stand out against other brands?

A: WiseCut goes beyond strong builds with top customization, certified service worldwide, and full ties to smart manufacturing. Find out more at WiseCut’s official site.