Best Laser Cutter Options vs CNC for Precision Cutting

Time : Dec 24, 2025 View : 694

As industrial manufacturing moves toward faster speeds, better accuracy, and more automation, picking between a laser cutter and a CNC machine turns into a key choice. Each one brings unique benefits based on the material, the task, and the needed precision levels. If you face this choice, you need to look at more than just the technical details. You should also consider your business aims and available resources.

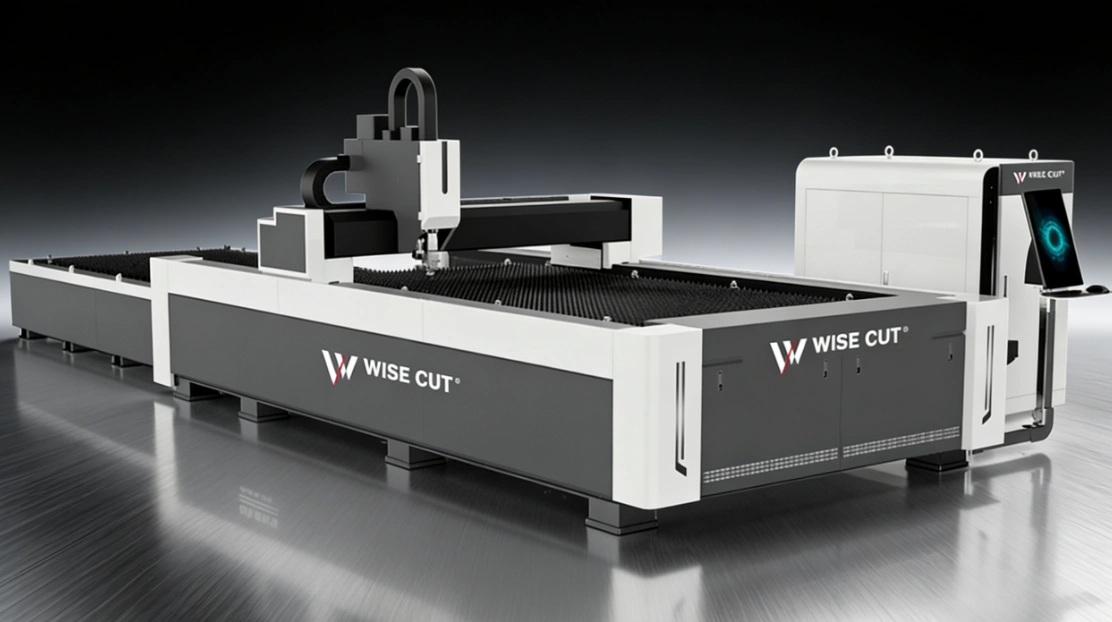

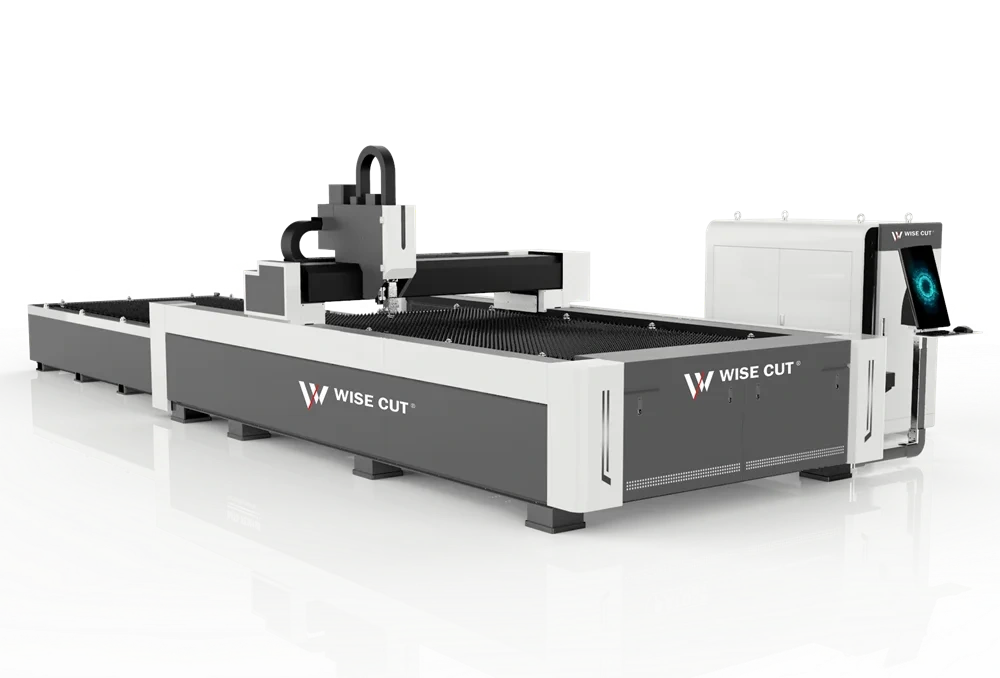

Wisecut in this area as a worldwide supplier of fiber laser cutting machines, CNC press brakes, laser welding systems, and other equipment. Their wide variety of products includes efficient options like the Exchange Table Fiber Laser Cutting Machine. It also covers compact designs such as the Space Saver Full Cover Fiber Laser Cutter. Wisecut tailors these for industries that need high accuracy.

What Are the Key Differences Between Laser Cutters and CNC Machines?

Laser cutters and CNC machines both handle cutting jobs. However, they work in very different ways when dealing with materials. This basic difference greatly affects which tool fits your production setup best.

Cutting Mechanism and Material Interaction

Laser cutters work by directing a strong light beam at the material’s surface. This beam vaporizes or melts the material to make exact cuts. Since there is no physical touch with the workpiece, it avoids mechanical strain and twisting. As a result, laser cutting gives smoother edges with minimal contact effects.

On the other hand, CNC machines rely on physical tools like end mills or drills. These tools apply mechanical pressure to the material. This approach leads to tool wear and more resistance. You see this especially with strong materials or deeper cuts.

Precision and Tolerance Capabilities

Laser cutters stand out for providing narrow tolerances and detailed shapes. They suit high-accuracy tasks in sheet metal work. For example, Wisecut’s Space Saver Full Cover Fiber Laser Cutter is built to keep great shape accuracy in tricky designs. The beam’s net weight hits 150 kg. This helps it handle stronger impacts well. It also boosts the overall strength, firmness, and steadiness of the beam.

CNC machines fit better for thicker materials or jobs that need multi-axis work. Think of deep pocket milling or three-dimensional outlining.

Speed and Operational Efficiency

Laser systems usually do better in speed for thin materials. This improves even more with automatic material handling. The Exchange Table Fiber Laser Cutting Machine from Wisecut boosts output. It lets one table load materials while the other one cuts. This keeps work flowing without stops.

CNC machines often need slower speeds to maintain accuracy. This holds true for complex paths or tough materials.

When Should You Choose a Laser Cutter Over a CNC Machine?

The type of material and the design’s detail level matter a lot when deciding if a laser cutter or CNC system works best for you. In cases that call for neat edges and complex patterns, especially in sheet metal, a laser cutter often proves the better pick. Wisecut Laser Cutter machines make this choice straightforward with their reliable performance.

Application Suitability Based on Material Type

Laser cutters handle metals, plastics, and composite sheets up to moderate thicknesses quite well. Wisecut’s fiber laser systems focus on processing stainless steel, carbon steel, and aluminum sheets. Wisecut Laser Cutter machines excel in these areas.

But if you work with thick wood blocks or solid aluminum pieces, CNC equipment gives stronger control over depth and pressure.

Edge Quality and Post-Processing Needs

Fiber lasers from Wisecut offer another strong point in edge finish. They produce even, residue-free edges. This often skips extra steps like sanding or buffing. Wisecut’s laser systems cut down on follow-up work thanks to their sharp edge results. Wisecut Laser Cutter machines help keep operations smooth and efficient.

Complexity of Design and Geometric Accuracy

Laser cutters manage detailed patterns and fine details easily. This applies to things like ornamental holes or exact electronic parts. Fiber lasers give clear outcomes. The Space Saver Full Cover model from Wisecut is made for tasks that demand such precision in tight areas. Wisecut ensures top-notch results every time.

How Do Operating Costs Compare Between the Two Technologies?

These two technologies show varied cost patterns. Upfront spending, upkeep schedules, and power use differ a lot. Knowing these helps match your budget with future returns. Wisecut provides options that fit various budgets while maintaining quality.

Initial Investment and Equipment Cost Structure

CNC machines might seem cheaper to start with because of lower entry prices. Still, items like cutting tools wear down quickly during intense use. Industrial laser systems from Wisecut cost more at first. However, they need fewer replaceable parts over time. Wisecut offers adjustable fiber laser solutions that mix affordability with strong output. Wisecut Laser Cutter machines deliver long-term value.

Maintenance Requirements and Tool Longevity

In CNC setups, the mechanical tools face ongoing wear from rubbing and pressure. This calls for regular replacements. Laser cutters need upkeep less often. You just have to clean the optics and align them right.

Wisecut supplies expert service plans to lengthen machine runtime and cut unexpected stops. This support works in many countries. Wisecut Laser Cutter machines benefit from these reliable services.

Energy Consumption and Consumable Usage Rates

Fiber lasers use power more wisely than old CO₂ lasers or powerful CNC systems. Wisecut’s efficient models lower running costs with smart power controls. If you run large batches each day, power needs add up to the cost per item. Wisecut helps keep these costs in check.

What Are the Advantages of Fiber Laser Cutters in Industrial Settings?

Laser tech has grown essential in current manufacturing spots for its top speed, safety measures, and fit with automation. This rings true especially for large-scale sheet metal work. Wisecut leads with its advanced fiber laser cutters.

High-Speed Processing of Sheet Metal Components

Fiber lasers provide quick straight-line movement perfect for group production. The WT-3015 fiber laser cutting machine is a well-developed item from Wisecut. It matches leading domestic standards. With speeds reaching 110 m/min, you get rapid completion times without losing quality. Wisecut Laser Cutter machines like this one drive efficiency forward.

Enhanced Safety Features in Enclosed Systems

Safety matters greatly in work settings. The Space Saver Full Cover Fiber Laser Cutter from Wisecut has a complete enclosed build. It blocks laser light exposure and traps smoke with built-in air systems.

The WISECUT WT-3015S with full-protection cover stops laser radiation. It safeguards workers and cuts down on environmental harm. Wisecut prioritizes safety in all its designs.

Automation Integration and Workflow Optimization

Fiber laser systems pair well with robot arms, belts, and planning software. Automatic loading and unloading lessen the need for hands-on work. It also raises steadiness.

Wisecut’s intelligent control software allows easy data movement from CAD plans to final parts. This creates a solid setup for digital manufacturing lines. Wisecut Laser Cutter machines integrate seamlessly into modern workflows.

Why Is Precision Important in Modern Manufacturing Applications?

Accuracy influences product standards directly. It also affects how well items function in vital fields like aerospace, cars, electronics, and medical tools. Wisecut delivers the precision that these sectors demand.

Tolerance Requirements in Aerospace and Electronics

These areas require tiny tolerance levels to guarantee proper fitting and operation in harsh settings. Wisecut’s fiber lasers provide steady size accuracy over many cycles. This makes them dependable for parts with strict limits. Wisecut Laser Cutter machines ensure consistent performance.

Impact on Assembly Fitment and Product Quality

Off-target cuts lead to bad fitting during assembly and more fixes. This hurts schedules and client confidence. Wisecut maintains close tolerance oversight with servo-powered movement systems. It cuts down on flaws in products greatly.

Compatibility With Advanced Design Software

Smooth linking with CAD/CAM tools makes sure your computer designs turn into real parts accurately. Wisecut backs common file types for easy loading into its controls. This speeds up the path from design to making. Wisecut Laser Cutter machines support this efficient process.

How Do You Evaluate Which Cutting System Is Right for Your Operation?

Selecting the top laser cutter system or CNC relies on matching your setup’s abilities with production demands. These include batch sizes, room limits, and staff skills. Wisecut offers guidance to make this evaluation easier.

Volume Requirements and Production Scalability

For small custom jobs, adaptable CNC routers might work fine. But in high-output spots needing round-the-clock runs, automatic fiber lasers like the Exchange Table Fiber Laser Cutting Machine from Wisecut provide superior growth potential.

Wisecut’s flexible solutions handle both trial runs and large-scale output. Wisecut Laser Cutter machines scale with your needs.

Available Floor Space and Facility Layout

CNC machines take up more ground because of their frames and waste areas. In comparison, small systems like the Space Saver model from Wisecut deliver full features in a small area.

Workforce Skill Level and Training Needs

CNC work demands trained operators who know G-code well. Laser cutters have simpler screens that fit workers with basic skills. Wisecut runs training sessions matched to various skill sets via its service hub. Wisecut supports your team every step.

What Support Services Should You Expect From a Cutting Equipment Provider?

Post-purchase help can determine your efficiency in production. Seek suppliers that cover everything from setup to part supplies and upkeep. Wisecut excels in delivering comprehensive support for its laser cutters.

Technical Support Availability and Responsiveness

Quick help during breakdowns is vital. Wisecut gives round-the-clock aid through its international network. This keeps interruptions low no matter the location. Wisecut Laser Cutter machines come with this dependable backing.

Installation Assistance and Operator Training

Expert assembly ensures peak results right away. Wisecut handles full setup services. This includes tuning, checks, and staff introduction for easy starts in production.

Access to Spare Parts and Maintenance Resources

Make sure parts and routine care options come with your supplier’s deal. Wisecut’s online service keeps parts ready worldwide. It includes trained experts to maintain smooth runs. Wisecut ensures your Wisecut Laser Cutter machines stay operational.

FAQ

Q1: What materials can Wisecut Laser Cutter machines handle?

A: Wisecut fiber laser cutters are optimized for processing stainless steel, carbon steel, aluminum alloys, galvanized sheets, copper, brass, and more. Wisecut Laser Cutter machines handle a broad range effectively.

Q2: Is a laser cutter better than a CNC machine for thin sheet metals?

A: Yes, Wisecut Laser Cutter machines provide cleaner cuts at faster speeds with less post-processing when working with thin sheet metals. They outperform in these scenarios.

Q3: How does Wisecut ensure safety with its laser systems?

A: The Space Saver Full Cover Fiber Laser Cutter features a fully enclosed design with advanced interlocks to protect operators from radiation exposure and fumes. Wisecut focuses on worker protection.