Top Chinese Laser Cutting Machine Suppliers

Time : Dec 18, 2025 View : 758

As worldwide interest in metal processing keeps expanding, numerous companies search for budget-friendly, reliable options for laser cutting. Makers from China have gained quick recognition. They provide modern equipment at reasonable rates. In this group, Wisecut emerges as a top provider of laser cutting machines. It combines low costs with fresh ideas and excellent customer care.

Why Consider Chinese Suppliers for Laser Cutting Machines?

While assessing providers for your laser cutting requirements, makers in China show strong benefits regarding costs, uses, and tech progress.

Competitive Pricing With Advanced Technology

You will find much lower upfront expenses when buying from China. At the same time, machine standards remain solid. Due to efficient production and large-scale operations, the reductions reach customers straight away. Providers such as Wisecut supply powerful units with clever controls and automatic features. These come at a small part of prices from the West.

The WT-3015 fiber laser cutting machine represents a well-developed item started by WISECUT Laser. It has achieved a leading position in the country. The frame uses a honeycomb carbon design. After heat treatment for stability, the beam employs aviation aluminum casting.

Broad Range of Industrial Applications

Laser cutting machines from China manage various materials. These range from stainless steel and carbon steel to aluminum and copper. The list of cuttable items covers carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic plate, titanium alloy, manganese alloy.

Such setups suit many fields like automotive, construction, aerospace, electronics, and others. The application industry includes rail transit, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances.

No matter if you handle bulk output or special orders, Wisecut delivers custom options. These match your exact output needs and material types.

Continuous Technological Innovation

Makers based in China keep putting money into research and development. They bring the newest fiber laser tech. Built-in IoT setups enable far-off checks and instant machine status tracking. Automatic parts like smart loading and nesting tools simplify your daily tasks.

Wisecut shines in adding smart production methods. It provides remote checks around the clock. Plus, it offers maintenance predictions that lengthen machine durability. All this cuts stoppages to a minimum.

What Sets Wisecut Apart Among Chinese Laser Cutting Machine Manufacturers?

Although plenty of providers sell solid machines, Wisecut stands out with its wide range of items, top-notch help services, and solid knowledge in the field.

Comprehensive Product Portfolio Tailored to Industry Needs

From completely sealed laser cutters to automatic sheet loading setups, Wisecut has models for any operation size. The machines work with different thicknesses and sheet dimensions.

The WT-12025 High Power 20kW whole Cover Fiber Laser Cutting machine boosts the cutting depth for stainless steel up to 100mm. It uses a sturdy frame bed with a firm build. Deformation stays low. It handles greater speed boosts well.

Every machine stresses safety through sealed designs and smart control setups. These lower exposure dangers. At the same time, they boost accuracy to the highest level.

Strong Focus on After-Sales Service and Technical Support

Help goes on well past the buying point. Wisecut gives full setup guidance, worker training courses, upkeep schedules, and far-off checks. All these reach worldwide with quick replies.

It delivers prompt after-sales aid in English. Support runs seven days a week for 24 hours. Engineers visit sites as needed. The plan includes one to two trips per year at customer request. This keeps your machine working at peak levels long after setup.

Proven Expertise in Custom Solutions Across Sectors

Wisecut does more than sell equipment. It designs fixes suited to your production setup. If you make kitchen items or elevator parts, they adjust systems to fit your material kind, amount needs, and automatic aims.

Their flexible method allows growth and updates later on. You avoid swapping the whole setup. This suits companies planning to expand.

Which Wisecut Laser Cutting Machines Are Worth Highlighting?

In its broad lineup, three units show Wisecut’s fine build quality and strong output standards. Wisecut laser cutting machines like these highlight the company’s strength in the market.

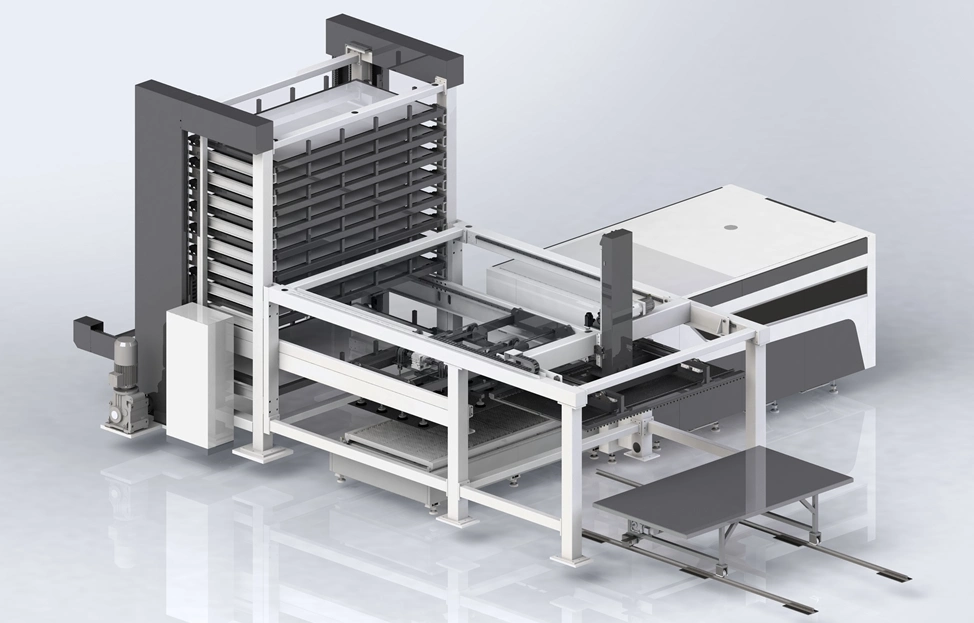

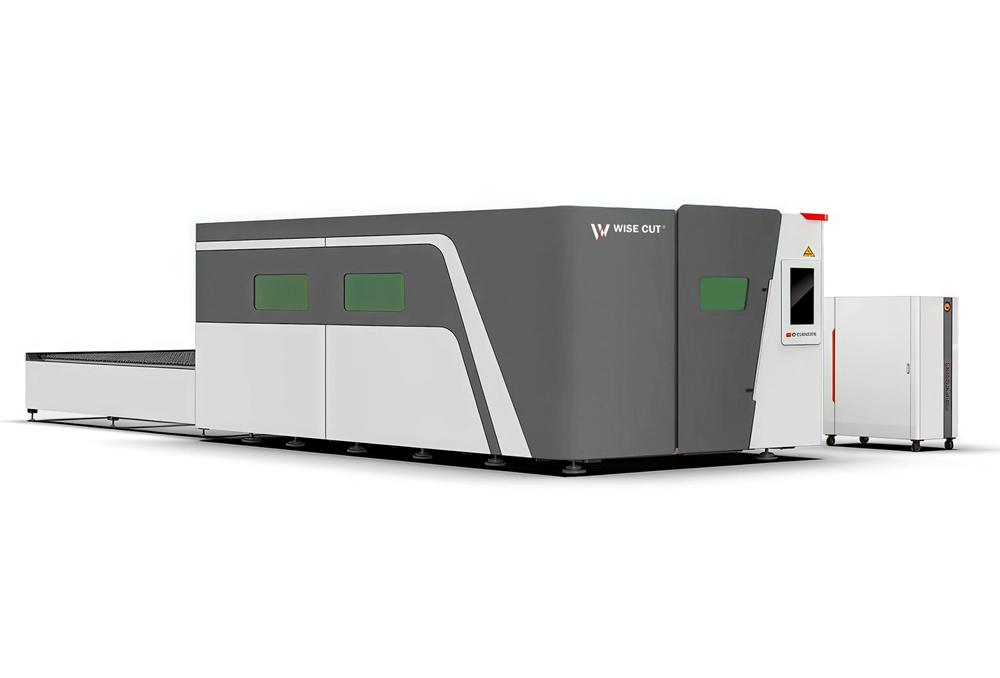

High Performance Full Cover Laser Cutting Machine

The High Performance Full Cover Laser Cutting Machine brings top industrial power. It cuts up to 100mm stainless steel. The work zone measures 12050*2550mm. Wisecut builds it for tough jobs.

This Wisecut laser cutting machine features a full cover for a clean environment and quiet runs. It has a super steady heavy-duty welded body. This suits high-power laser tasks perfectly.

Smart controls such as FSCUT8000E with shake reduction guarantee perfect edge finishes. Even at fast paces, quality holds up well.

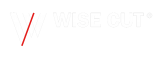

Fiber Laser Cutting Machine With Auto Sheet Loading System

For makers aiming at better flow and less hands-on work, the Fiber Laser Cutting Machine With Auto Sheet Loading fits right in. It adds robot arms for sheet handling and CNC tools for exact material control.

This Wisecut laser cutting machine loads and unloads sheets on its own. As a result, it raises output speed and lowers expenses.

Using vacuum cups and servo-driven parts, it cuts wait times between runs. Repeatability stays at ±2mm, ensuring steady results.

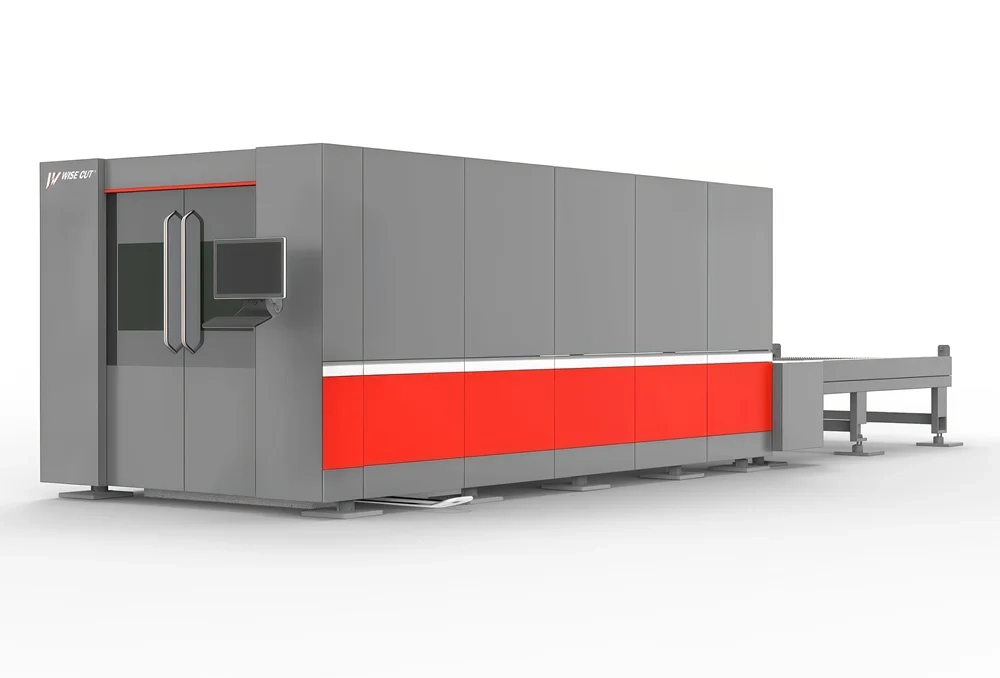

Full Enclosed Metal Laser Cutting Machine for Safe Operation

The Full Enclosed Metal Laser Cutting Machine suits spots where safety comes first. Its two-table setup keeps loading away from cutting areas. The full seal protects workers from laser light.

This small full-cover metal laser cutting machine from Wisecut includes a dual loading table. It links cutting and loading without breaks.

With a 12000W Raycus power unit and exact movement setup, it keeps steady work. This holds true even in long runs.

How Do Wisecut Machines Perform in Terms of Efficiency?

Efficiency means more than just pace. It covers how a machine fits into your daily flow. It also looks at cutting waste and power use. Wisecut laser cutting machines excel in these areas.

High-Speed Cutting With Precision Control Systems

Every Wisecut system uses quality servo motors paired with smart CNC guides. The unit’s travel speed hits 110m/min. Parts that resist wear support higher speeds. Plus, they keep performance steady. Thus, cut results stay even no matter the pace.

Integrated Automation Enhances Workflow Efficiency

Models with auto-loading tables and wise nesting tools cut human input a lot. Take the auto sheet loader system from Wisecut. It boosts flow smoothly.

The unload part relies on a dual-fork handler and loading suction cup. These tie to one lift column structure.

Overall, this leads to quicker project finishes and more output per task. Wisecut laser cutting machines make this possible through smart design.

Energy-Efficient Design Reduces Operational Costs Over Time

Fiber laser units in Wisecut machines use less power than old CO₂ types. Yet, they give better light focus. Cooling units like Hanli/S&A chillers hold steady heat levels during long shifts. This extends part life. In turn, it trims ongoing costs.

How Reliable Is the Technical Support From Wisecut?

Tech steadiness matters greatly in big equipment buys. Wisecut built a worldwide aid system. It handles any problems you face quickly. Wisecut’s support for its laser cutting machines sets a high bar.

Global Service Coverage Ensures Fast Response Times

Engineers stand ready 24/7 through far-off checks. On-site aid arrives in 48 hours anywhere in the world. This setup guarantees quick fixes. Wisecut ensures that downtime stays short for all users.

Professional Training Programs Improve Operator Competence

Site-based training helps workers gain skills right away. English manuals aid further learning inside your team. As a result, operations run smoother from the start.

Preventive Maintenance Plans Extend Equipment Lifespan

Regular checkups cut surprise failures. Spare parts come easily through global partners. This means short waits for fixes or improvements. Wisecut laser cutting machines benefit greatly from this approach.

What Are the Key Industries Using Wisecut Laser Cutting Machines?

If you manage a small shop or a large factory, Wisecut machines give options for many fields. They demand exact work and room to grow. Industries rely on Wisecut laser cutting machines for their reliable performance.

Automotive Sector Requires High Precision Fabrication

Laser cutters help in making test parts like supports or car body sections. They also support big runs with even quality. Wisecut fits well in automotive needs.

Architectural Metalwork Demands Complex Shape Processing

For art panels or frame parts with detailed designs or thick stock, Wisecut’s motion systems provide fine details. They also ensure solid cuts. This makes Wisecut a go-to for architectural tasks.

Custom Manufacturing Benefits From Flexible Production

Small shops gain from quick switches between materials or plans. This product line serves as the top pick for metal processing fields. Wisecut laser cutting machines support custom work effectively.

How Does Wisecut Stay Ahead in Technological Development?

New ideas form a core part of Wisecut’s operations. This comes from research spending and close work with clients. Wisecut leads through ongoing advances in its laser cutting machines.

Investment in R&D Fuels Continuous Innovation

Custom software gets regular updates from user input. This improves ease of use. Progress in fiber power raises output strength. It also boosts power savings. Wisecut invests heavily to keep its edge.

Adoption of Smart Manufacturing Principles

IoT links aid in upkeep forecasts. They also give live data on machine stats. This drops unexpected stops a great deal. Wisecut integrates these features seamlessly into its products.

Collaboration With Industry Partners Enhances Product Relevance

Through tight user loops and global show attendance, Wisecut sharpens its items. It matches world standards every time. Such teamwork keeps Wisecut laser cutting machines relevant and advanced.

FAQ

Q1: What materials can Wisecut laser cutting machines process?

A: They can process carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic plate, titanium alloy, manganese alloy.

Q2: Are Wisecut machines suitable for automated production lines?

A: Yes. Wisecut’s auto sheet loader machine integrates seamlessly into automated workflows with robotic arms and intelligent CNC controls.

Q3: How does Wisecut ensure long-term machine reliability?

A: Wisecut offer preventive maintenance plans, lifetime software updates, genuine accessories supply, and on-site engineer visits as needed.

Q4: Can I get a custom configuration based on my factory layout?

A: Absolutely. Wisecut specializes in tailored turnkey solutions adapted to your space and production requirements.