Achieving Perfect Edges: How Laser Cutting Guarantees Smooth, High-Quality Surfaces

Time : Jan 21, 2026 Visualizzazione : 43

Are secondary finishing processes like grinding and deburring eating up your profit margins? In industries like aerospace and medical manufacturing, edge quality isn’t just an aesthetic choice—it’s a high-stakes performance requirement.

In this discussion, we will examine how reliable laser cutting options from WiseCut provide top-notch, smooth edges without rough spots, along with steady results. At the same time, these systems cut down on extra finishing steps and boost productivity in general.

What Makes Laser Cutting Ideal for Achieving Smooth, High-Quality Edges?

As a High-tech Enterprise certified by the China Ministry of Science and Technology in 2020 , WiseCut integrates decades of R&D into our motion control systems to eliminate micro-vibrations.

Precision Cutting with Minimal Thermal Distortion?

The key strength of a high-precision laser cutting machine comes from its skill in offering exact cuts while limiting heat-related issues. The laser beam creates a slim gap and directs energy precisely, which lets it move through metal with great accuracy. This matters a lot for detailed shapes or strict limits on size.

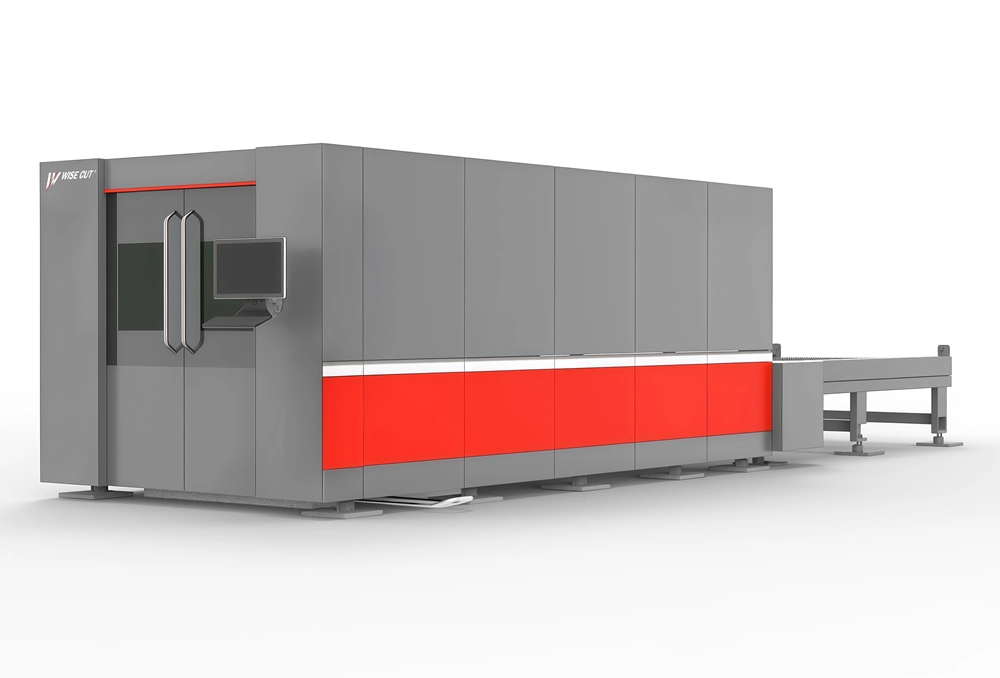

WiseCut’s High Performance Full Cover Laser Cutting Machine handles thicknesses up to 70 mm. It achieves speeds of 120 m/min during operation. With this capability, clear edges on heavier materials are now possible. The small area affected by heat helps prevent bending of the material. It also keeps the original strength intact. As a result, laser cutting outperforms conventional heat-based approaches.

Clean Separation Without Burrs or Post-Processing?

Traditional tools that use force or rubbing create stress or rough edges on the material. In contrast, laser beams turn the material into gas right at the cutting path. This process avoids mechanical strain or unwanted buildup. Therefore, you skip steps like smoothing or polishing, which saves time and money.

Il Piattaforma singola macchina per il taglio laser della lamiera excels here. It has a beam made from cast aluminum, which offers strong support yet remains lightweight. This design guarantees steady and precise cuts, particularly on slim sheets.

High Repeatability for Industrial Applications?

Laser equipment with computer numerical control systems enables exact duplication of detailed designs. These CNC-guided laser setups produce matching cuts over extensive batches. No matter if you make a single piece or thousands, the standard remains the same.

WiseCut includes modern automation features that handle large-scale output. At the same time, it upholds accuracy throughout the process. This suits producers who need reliable results without any shortcuts.

Based on our collaboration with a European distributor, WiseCut’s precision customization allowed them to deliver over 50 units to niche markets where standard models failed to meet edge tolerance requirements.WiseCut’s bespoke engineering strategy helped a European partner secure orders for over 50 machines by fine-tuning power and speed to match their specific 0.03mm tolerance requirements.

How Does the Type of Material Influence Edge Quality in Laser Cutting?

Thermal Conductivity and Melting Point Considerations?

Those with reduced heat transfer create neater edges because the warmth stays in one spot. For example, stainless steel works better with laser cutting than aluminum. This happens due to its gradual release of heat.

WiseCut laser devices are designed to manage many types of heat-conducting metals. They use specific settings for each, so you can change materials easily. Edge standards stay high no matter what.

Surface Reflectivity and Absorption Rates?

Metals that reflect light strongly, such as copper and brass, can bounce back the laser energy. Here, adjusting the light wavelength and sharpening the beam become vital. Correct choices in wavelength and focus are essential for handling items like copper or brass.

WiseCut’s superior lens systems keep the cutting process effective on shiny surfaces. Thus, challenging materials do not lower the overall performance.

Material Thickness and Structural Density?

Slicing a thin 2 mm aluminum sheet differs greatly from handling a dense 25 mm carbon steel piece. Heavier items demand more power to keep edges neat. Compact materials often require reduced speeds to prevent too much warmth.

Il Macchina di taglio laser a copertura completa ad alte prestazioni proves its value in these scenarios. It works with laser power reaching 30kW. The cutting space extends to 12050*2550mm. This setup delivers even results on substantial plates without issues.

Why Is Beam Quality Essential for Edge Smoothness?

Beam Focus and Spot Size Control?

A beam that stays sharply aimed is crucial for thin cut lines and defined borders. Such focus limits the width of the gap and sharpens the edge details. The tinier the light point, the better the precision of the slice.

WiseCut machines come with smart focusing tools that adjust quickly to shifts in material. They ensure that edge sharpness holds up across different depths.

Power Density Distribution Across the Beam Profile?

Uneven warm areas in the beam path might harm the edge finish and lead to varied outcomes. Even spread of energy avoids those problem spots that could roughen the surfaces.

WiseCut’s beam adjustment methods improve evenness during fast runs. This plays a big role in expanding output while holding onto exactness.

Pulse Frequency and Modulation Capabilities?

Controlling the amount of heat is important when moving between materials or changing depths in a single project. Adjustments in pulsing allow finer management of edge angles and surface polish. Quick pulses can also cut down on residue buildup.

WiseCut offers flexible pulse options matched to specific needs. These improve the evenness of surfaces in diverse situations.

How Do Cutting Parameters Affect Final Edge Quality?

Speed-to-Power Ratio Optimization?

Finding the right mix of movement speed and energy output requires care. Moving too quickly might leave residue. Going too slowly could build up too much heat.

WiseCut supplies user-friendly programs to adjust these elements based on the task. This cuts down on testing phases significantly.

Assist Gas Type and Pressure Settings?

The kind of gas used has a major impact on how clean the edges turn out. Oxygen boosts the pace of cutting, but it might cause rust on the surfaces. Nitrogen creates purer finishes without oxidation. Controlling the pressure also shapes the cut width and waste removal.

WiseCut machines enable exact handling of gas to fit the material needs. They even include options for two gases in tougher jobs.

Nozzle Diameter and Stand-Off Distance Calibration?

The size of the nozzle plays a role in steady gas flow at the cutting area. The gap between the nozzle and the piece influences the depth of focus and the evenness of the cut.

WiseCut provides automatic adjustment tools to keep the nozzle in place during the entire process. This proves helpful in varied production setups.

What Role Does Machine Design Play in Edge Precision?

Structural Rigidity of the Machine Frame?

Movement of the machine, particularly at quick paces, might cause shakes that affect edge accuracy. A firm base reduces those vibrations and supports steady paths during rapid cuts.

The High Performance Full Cover Laser Cutting Machine employs a sturdy welded foundation. It endures ongoing stress when working on heavy plates.

Motion Control System Responsiveness?

Accurate motion depends not only on the drives but also on their immediate reactions. Gradual starts and stops in speed help avoid rounding at turns on edges.

WiseCut uses feedback-based motion controls that hold exact positions even at 120 m/min speeds.

Enclosure Design for Environmental Control?

Changes in temperature can disrupt the stability of the light path. Closed setups shield from particles, heat variations, and outside factors.

WiseCut’s covered designs create a stable environment perfect for detailed work in factory settings.

How Does Software Integration Enhance Edge Quality?

Real-Time Monitoring of Cut Conditions?

The laser’s performance might vary during use because of rising temperatures or uneven materials. Detection tools follow warmth levels, pace, and light strength as things progress.

WiseCut software has built-in checks that run ongoing assessments to sustain quality in each run.

Advanced Nesting Algorithms for Efficient Layouts?

Bad placement of parts can cause heat to build up in spots. Smart arrangement of pieces lessens that heat pile-up near cuts.

WiseCut’s planning software delivers clever placement methods suited to different tasks. It protects edge quality at bends and narrow areas.

Customizable Cut Profiles Based on Material Database?

Rather than tweaking settings by hand every time you change materials, ready-made options handle it automatically. These stored setups speed up preparation by using the best values for each material size and type.

WiseCut software holds a broad collection of adjustable defaults. This gives users room to adapt, allowing beginners to reach skilled results right away.

Why Choose Wisecut Machines for High-End Edge Finishing?

Seeking more than merely precise edges? WiseCut provides far beyond basic equipment. It delivers a complete setup of tools, programs, and assistance customized to your operations. From fiber laser cutters built for tiny tolerance tasks to automated systems that blend smoothly into your workflow, all elements focus on flawless execution, run after run.

Wisecut’s equipment aligns with global benchmarks for strength, exactness, and dependability. This positions them as dependable allies in tough areas like aerospace and medical production.

Need support at any point? The 24/7 service team stands ready with a simple contact. They offer worldwide coverage combined with area-specific knowledge to guide you from setup to growth in output.

Discover additional details at WiseCut. Here, superior edge quality represents not only a commitment but a reality in every unit delivered around the globe.

Domande frequenti

Q1: How does laser cutting prevent burr formation?

A: The laser beam vaporizes material at the cut zone instead of shearing it mechanically, which eliminates burrs and reduces the need for post-processing like grinding or sanding.

Q2: Which materials benefit most from laser cutting in terms of edge quality?

A: Metals like stainless steel, carbon steel, aluminum alloys, copper, and brass are well-suited due to their thermal properties; each responds differently based on conductivity and reflectivity.

Q3: Can Wisecut machines handle thick metal sheets while maintaining smooth edges?

A: Yes. The High Performance Full Cover Laser Cutting Machine supports up to 70 mm thickness with minimal heat distortion thanks to its powerful laser source and stable frame structure.

Q4: Is real-time monitoring available during cutting operations?

A: Yes. Wisecut’s integrated software tracks key metrics such as temperature and beam intensity and adjusts parameters dynamically to maintain consistent cut quality.

Q5: How does assist gas affect the final edge finish?

A: Using nitrogen helps produce cleaner, oxidation-free edges, whereas oxygen increases cutting speed but may leave oxidized surfaces requiring additional treatment.