Top 10 Laser Tube Cutting Machines in the World 2025

Time : Dec 25, 2025 View : 776

The worldwide need for reliable tube fiber laser cutting machines keeps growing. Industries want better accuracy, quicker operation, and smoother automation. In 2025, picking a strong machine depends on its cutting features, fresh technology, and steady performance. This overview looks at the main ways to rank them. It points out top options in the field. It also explains why makers looking for good results and value should turn to Wisecut. Wisecut remains a trusted leader in laser cutting tools.

What Are the Key Criteria for Ranking Tube Fiber Laser Cutting Machines in 2025?

To pick the best tube laser cutters around the world, you need to check them based on clear technical results, smart design, and actual user comments. These factors make sure your spending matches your work aims.

Performance Metrics and Cutting Capabilities

You start checking with how fast it works, how exact it is, and what kinds of materials it takes. The top machines deal with round shapes, square ones, and special forms. They use quick turning and leave little waste at the end. The strongest setups manage sizes from Φ10 mm to Φ500 mm. They also handle lengths up to 12 meters. All this comes with a repeat accuracy of ±0.02 mm. For instance, the 3 Chuck Heavy Duty Tube Laser Cutting Machine gives quick, adaptable, and firm cutting for big pipes. It ensures no waste at the end. Plus, it boosts how well you use materials.

Technological Innovation and Automation Level

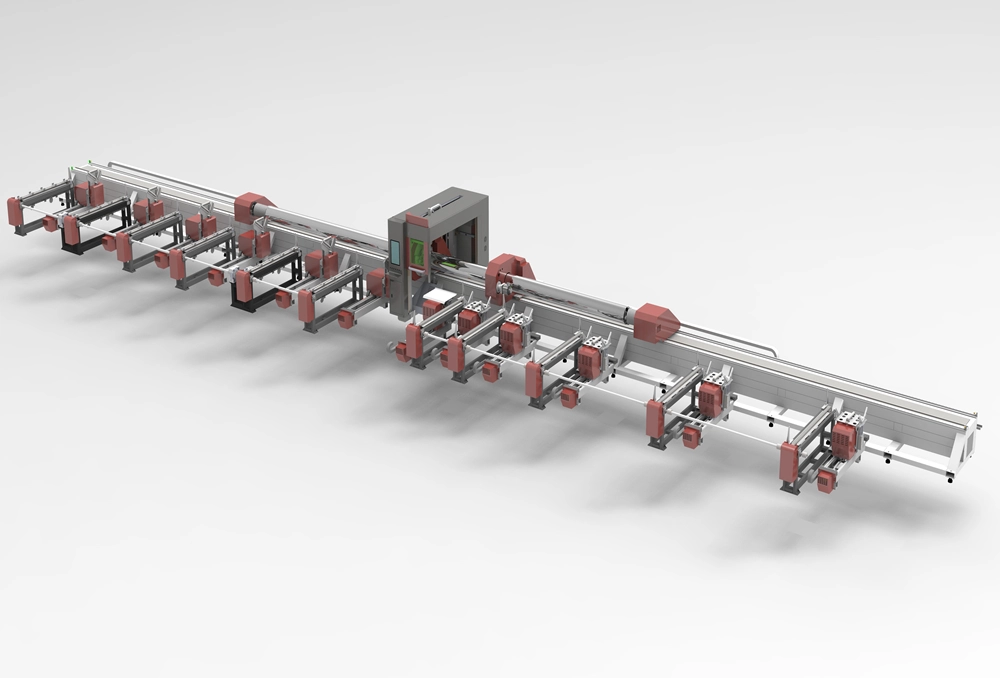

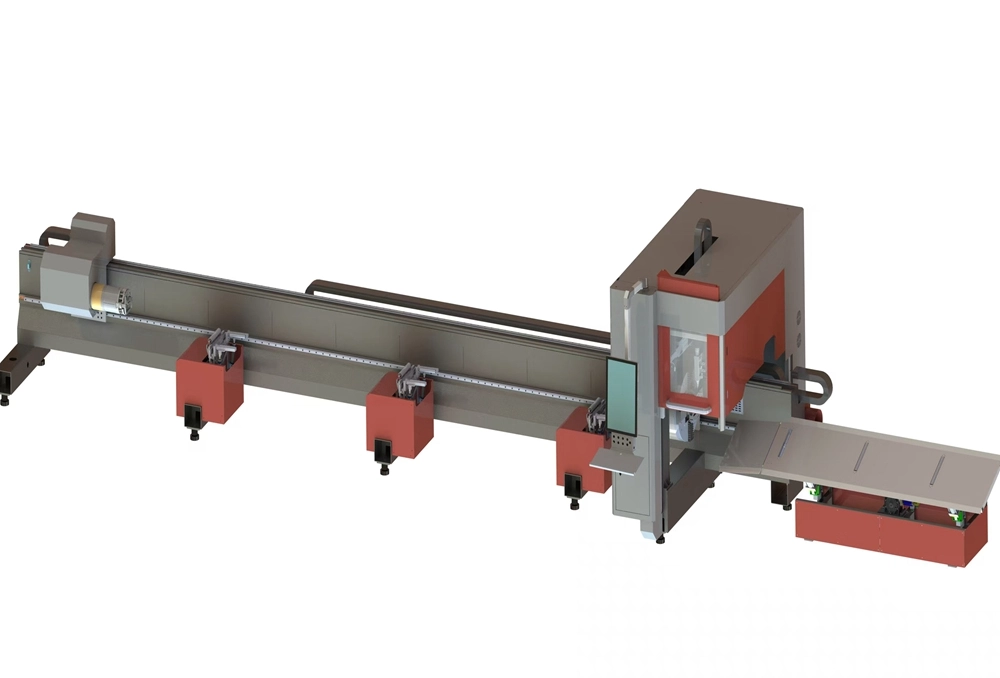

Modern tube fiber laser cutters come with smart software for placing parts, controls on many axes, and auto systems for loading and unloading. They link with servo setups and clever chucks. This allows cutting with no leftover material. The 4 Chuck Profile Heavy Laser Tube Cutter has four chucks for backward cutting. It helps use the full pipe length. It also cuts down time lost to hand work.

Market Reputation and After-Sales Support

Trust around the world comes from solid builds and helpful service. Seek brands with CE-certified units, ISO9001 standards, and support in many languages. Wisecut offers prompt after-sales help in English, available 7 days a week for 24 hours. This includes sending spare parts and planned visits to customers.

Why Is Wisecut a Leading Brand in Tube Fiber Laser Cutting Machines?

Wisecut shines as a maker from around the world. It supplies advanced tools for metal work in more than 20 countries. Wisecut focuses on full options to fit needs and smart auto features. It has changed how factory workers handle laser tube cutting.

Comprehensive Product Line for Diverse Applications

No matter if your work needs small precise cuts or big heavy jobs, Wisecut’s range covers it. You can find the Two chuck Pipe Laser Cutting Machine. There is also the 3 Chuck Heavy Duty Tube Laser Cutting Machine. Wisecut offers the 4 Chuck Profile Heavy Laser Tube Cutter. And for combined use, Wisecut provides the Sheet & Tube Metal Fiber Laser Cutting Machine.

Advanced Manufacturing Technology and R&D Strength

Wisecut Laser shows great skill in research. The skilled team at Wisecut has earned over 300 patents. Wisecut machines use smart focus parts, top servo motors from Japan Fuji, and sectioned frames for strong builds. Every laser system from Wisecut ties in high-level CNC controls like CYPCUT.

Global Service Coverage with Industry Expertise

Quick 24/7 checks from afar plus engineers on site in 48 hours anywhere keep work running without stops. Wisecut’s help plan covers training for users, checks from remote spots, updates to software, and yearly visits to clients. You can learn more about all this at Wisecut Services.

Which Machines Define the Top 10 Laser Tube Cutters in 2025?

Wisecut machines lead the world rankings. They stand out due to power levels, build style, auto features, and how well they fit different uses. Here are some key ones from Wisecut.

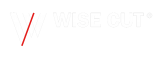

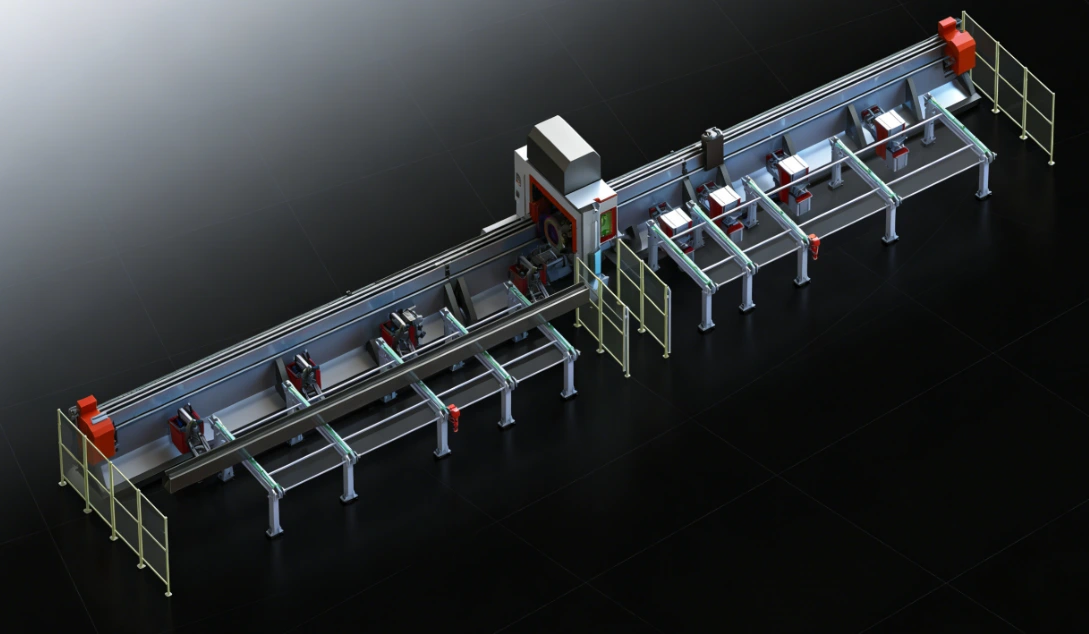

Wisecut 4 Chuck Profile Heavy Laser Tube Cutter

This unit from Wisecut is built for very heavy shapes up to Φ500mm wide and 12m long. The four-chuck setup allows clamping on all sides for no end waste. It supports cutting from the back. Wisecut designs it for uses in building bridges, making ships, and big steel projects.

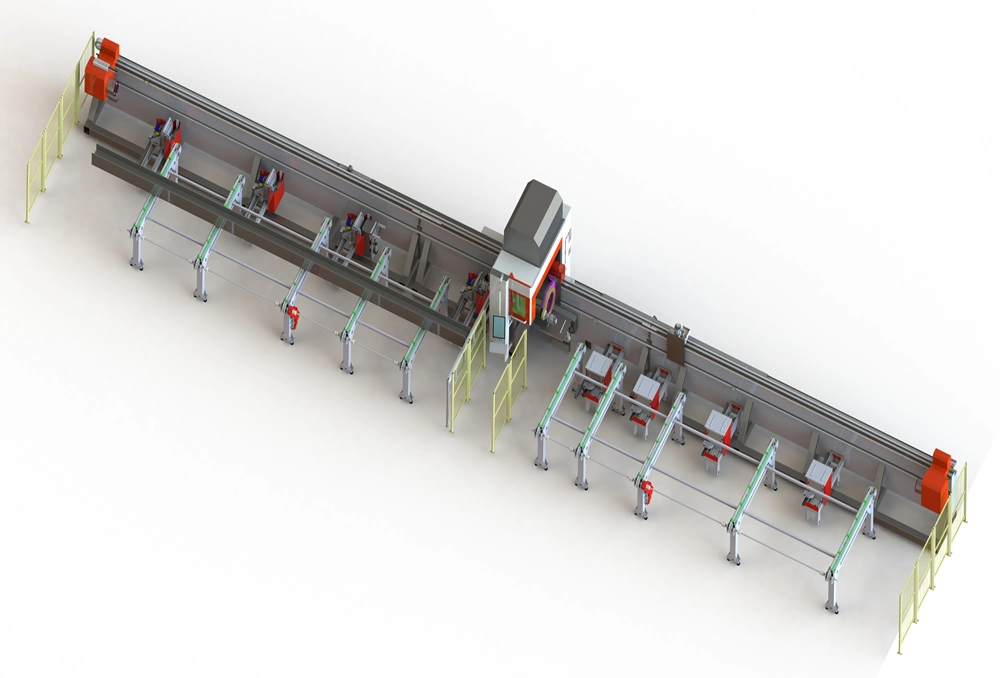

Wisecut Sheet & Tube Metal Fiber Laser Cutting Machine

This Wisecut machine mixes sheet work on areas up to 3050x1550mm with tube jobs up to Φ220mm. It raises flexibility by half using two setups. Wisecut makes it great for shops that switch fast between flat pieces and tubes.

How Do These Machines Improve Production Efficiency?

Work output no longer faces limits from hand tasks or poor part placement. Wisecut systems add clever auto steps to each part of the process.

Integrated Automation for Unmanned Operation

This setup loads and unloads sheets on its own. It raises work speed and lowers expenses. For example, chain feeders let one worker handle several lines at once. Wisecut ensures smooth runs with these features.

Intelligent Nesting and Real-Time Monitoring Systems

Software for placing parts cuts scrap even in tricky shapes. Wisecut gives free updates to software for life. It keeps adding to lists of settings for cutting, bending, and welding. This helps clients work better over time.

High-Speed Precision with Stable Repeatability

Imported servo motors and exact gears from Japan and Taiwan make these Wisecut machines steady. They keep ±0.02mm accuracy the same even at speeds over 90 m/min. Wisecut focuses on reliable results in every cut.

What Role Does Machine Design Play in Long-Term Performance?

Exact building goes further than just the cutting parts. It shows in every part of the machine frame.

Rigid Frame Construction for Vibration Reduction

The bases of Wisecut machines go through heat treatment and extra shake aging. This removes built-up stress inside. As a result, Wisecut units last well under full-time factory use.

Modular Chuck Systems for Flexible Pipe Handling

Each Wisecut model takes square, rectangle, round tubes, and even I-beams. It uses air-powered centering chucks from Φ10 mm to Φ500 mm. This setup from Wisecut allows easy changes for different jobs.

Smart Dust Removal and Cooling Mechanisms

Wisecut equips units with top vents for easy fixes and ports to pull out bad air fast. Chillers from Hanli keep the laser cool and steady. This extends how long Wisecut machines run without issues.

How Does After-Sales Support Influence Equipment Investment?

A fine machine needs strong backing from a forward-thinking service team. This cuts stop times and guards value over years.

On-Site Commissioning and Operator Training Services

Wisecut will train machine users for free at the factory. The training lasts until they grasp the unit’s build and how it works fully. This gets workers ready to produce right away.

Remote Diagnostics and Software Updates from Wisecut Team

Wisecut leads with training classes and help from afar. Problems get fixed online or with planned visits from field experts in 48 hours across the world.

Global Spare Parts Availability with Fast Delivery Commitment

Wisecut keeps stock in spots across Europe and Asia-Pacific. Quick service for parts and extras shortens wait times. It helps keep Wisecut machines working without breaks.

Why Should Consider Wisecut for Their 2025 Equipment Upgrade?

You aim to lower cost per piece, handle various fields, and see quick returns. Wisecut brings value that others can’t match.

Proven Industry Experience Across Multiple Sectors

Wisecut helps fields like car making, gym gear, building tools, bridges, and tunnels. It offers plans fit to real work problems. Wisecut draws from years of know-how in these areas.

Customizable Solutions Tailored to Production Needs

Wisecut builds machines to order when asked. If you want quicker loading, thicker materials, or better looks on finishes, Wisecut adjusts to meet those. This personal touch from Wisecut fits your setup perfectly.

Competitive ROI Backed by Technical Excellence

Strong build means fewer fixes. Auto features cut worker needs. Software tweaks lower waste. All this from Wisecut leads to cheaper cuts in the long run.

Check out more via Wisecut’s official product catalog. Or reach out straight through the contact page.

FAQ

Q1: What tube sizes can Wisecut machines handle?

A: Wisecut machines manage pipes from Φ10 mm up to Φ500 mm based on the model you choose.

Q2: Can I use one machine for both sheet and tube processing?

A: Yes, the Sheet & Tube Metal Fiber Laser Cutting Machine lets you switch easily between flat parts and tubes.

Q3: How does Wisecut ensure long-term machine stability?

A: Wisecut treats each base with heat annealing and shake aging to remove stress from welding.

Q4: What kind of after-sales support does Wisecut offer internationally?

A: Wisecut plans engineer visits 1-2 times a year if requested, along with 24/7 checks from afar worldwide.

Q5: How do I get a quote or technical consultation?

A: Go to the contact page. Or send a message via WhatsApp or email for fast help.